Understanding Boiler Tubes: Structure and Function

Boiler tubes are integral components of industrial boilers, responsible for efficiently transferring heat from the combustion process to water, generating steam or hot water for various applications. These boilers are widely used across industries, including power plants, petrochemical refineries, food processing, and pulp & paper mills.

Boiler tubes serve as conduits for water or steam and are continuously exposed to extreme temperatures and pressures. Over time, deposits of scale, soot, and corrosion accumulate inside these tubes, impairing heat transfer and increasing the risk of overheating, energy inefficiency, and potential tube failure. Without proper cleaning and maintenance, these issues can escalate, leading to expensive repairs, safety hazards, and unplanned downtime.

Why High-Pressure Cleaning Pumps Are Crucial for Boiler Tube Maintenance

Boiler tubes require regular cleaning to maintain peak performance and extend their operational lifespan. High-pressure cleaning pumps are one of the most effective and eco-friendly solutions for this purpose. Here’s how they ensure optimal boiler performance:

1. Efficient Removal of Deposits and Contaminants:

Boiler tubes accumulate different types of deposits, including:

- Mineral Scale – Hard deposits from calcium and magnesium in water.

- Soot and Ash – Combustion by-products that insulate tubes and lower heat transfer.

- Corrosion and Sludge – Rust and impurities that reduce boiler efficiency.

High-pressure cleaning pumps generate powerful water jets that effectively dislodge and remove these deposits, restoring heat transfer efficiency and ensuring even temperature distribution across the tubes.

2. Prevention of Tube Failures and Safety Hazards:

Deposits can cause localized overheating, leading to hot spots that weaken the metal structure of boiler tubes. If left unchecked, this can result in tube ruptures, which not only lead to costly shutdowns but also pose serious safety risks to personnel.

Regular high-pressure cleaning minimizes these risks by ensuring boiler tubes remain free from obstructions, preserving their structural integrity and preventing unexpected failures.

3. Enhancing Energy Efficiency and Reducing Fuel Costs:

A clean boiler operates at optimal thermal efficiency, meaning it requires less fuel to produce the same amount of steam or hot water. When tubes are clogged, heat transfer is impeded, forcing the boiler to consume excess fuel to reach the required temperature. High-pressure cleaning pumps help improve efficiency, resulting in lower energy consumption and reduced operational costs.

4. Reducing Maintenance Downtime and Improving Reliability

Boiler tube cleaning is a preventive maintenance practice that significantly reduces the likelihood of emergency breakdowns. High-pressure water jet cleaning is faster and more effective than traditional cleaning methods, enabling industries to maintain uninterrupted operations and avoid costly downtime.

5. Eco-Friendly Cleaning Alternative:

Unlike chemical descaling, which requires the use of harsh chemicals that can be hazardous to the environment, high-pressure cleaning pumps use only water, eliminating chemical waste and disposal concerns. Additionally, this method reduces the risk of tube damage compared to mechanical or abrasive cleaning techniques.

6.Adaptability to Different Boiler Types and Deposits:

High-pressure cleaning pumps come with adjustable pressure settings, making them versatile for different applications:

- Low-pressure cleaning for delicate tube surfaces.

- Medium-pressure cleaning for moderate soot and scale removal.

- Ultra-high-pressure systems (above 1000 bar / 15,000 psi) for industrial-scale stubborn deposits.

This flexibility ensures effective cleaning across a variety of boiler tube materials and contamination levels.

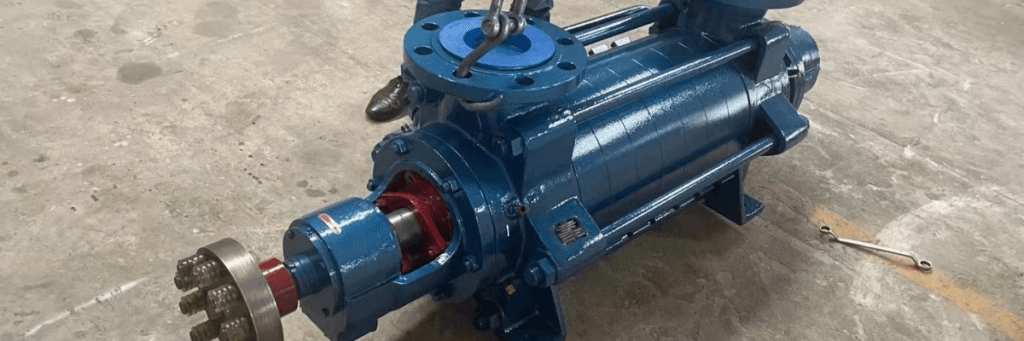

Types of High-Pressure Pumps for Boiler Tube Cleaning:

- Electric High-Pressure Pumps: Suitable for medium to large-scale industrial cleaning tasks. They are reliable and efficient for continuous use.

- Diesel/Gasoline High-Pressure Pumps: Ideal for remote or outdoor cleaning operations where electricity may not be available. These are often used in industries such as oil refineries and power plants.

- Ultra-High-Pressure (UHP) Systems: These pumps operate at pressures over 1000 bar (15,000 psi) and are used for the most stubborn deposits and large industrial boilers.

Key Industrial Applications of High-Pressure Cleaning Pumps:

- Power Generation: Boilers in power plants must operate efficiently to produce steam for electricity generation. High-pressure cleaning ensures that the boilers are free of contaminants and capable of delivering maximum output.

- Petrochemical and Refineries: Removes heavy deposits from process boilers, ensuring compliance with industry safety standards.

- Food Processing: Maintains hygiene and efficiency in steam-based sterilization and heating systems.

- Pulp and Paper Mills: High-pressure cleaning of boiler tubes ensures the smooth operation of boilers, which are critical for various heating processes in paper production.