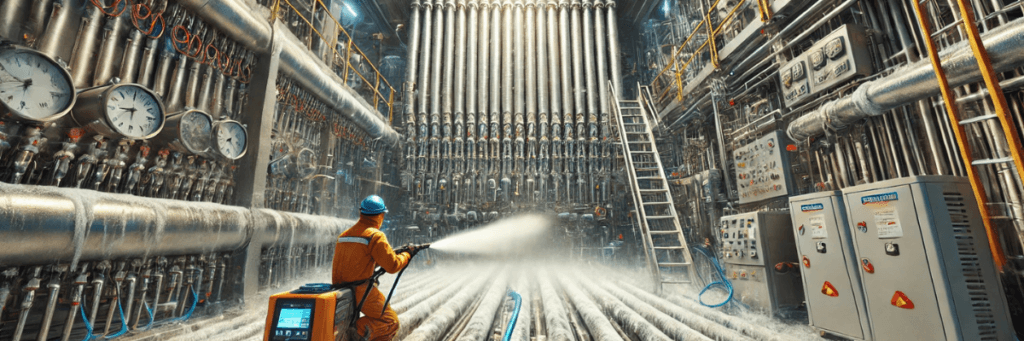

Chiller tubes play a crucial role in the operation of chiller systems, commonly used in industrial, commercial, and HVAC applications for cooling processes. Over time, these tubes can accumulate scale, biofilm, sludge, corrosion, and mineral deposits, which reduce the efficiency of heat transfer, increase energy consumption, and lead to system malfunctions. To ensure optimal performance, high-pressure cleaning of chiller tubes is a highly effective maintenance practice. Here’s why it is essential:

1. Maximizing Heat Transfer Efficiency

The primary role of chiller tubes is to transfer heat between refrigerant and cooling water. However, when dirt and scale accumulate, they create an insulating barrier that reduces heat exchange efficiency.

- Removes stubborn deposits, restoring full heat transfer capacity

- Enhances cooling efficiency without increasing system load

- Prevents overheating, ensuring consistent chiller operation

Example Impact:

According to industry studies, even a 0.03-inch layer of scale can reduce heat exchanger efficiency by up to 25%, significantly increasing energy costs.

2. Cutting Down Energy Consumption & Costs

- Higher energy consumption

- increased wear on pumps, compressors, and fans

- Greater risk of system strain and component failure

Why High-Pressure Cleaning Saves Energy:

- Clears obstructions, allowing for optimal fluid flow

- Reduces the workload on pumps and compressors, cutting electricity usage

- Lowers monthly energy bills—a major cost factor in large facilities

Studies show that a 15% reduction in chiller efficiency due to dirty tubes can lead to a 30% increase in energy costs annually.

3. Extending Chiller System Lifespan

Contaminants in chiller tubes speed up corrosion, pitting, and structural erosion, leading to premature failures. If left unchecked, this can result in:

- Costly tube replacements

- Frequent system breakdowns

- Reduced equipment lifespan

How High-Pressure Cleaning Protects Your Investment:

- Removes corrosive deposits, slowing down tube degradation

- Prevents leaks, cracks, and pressure loss

- Extends the life of critical components, delaying major replacements

- Real-World Example:A manufacturing plant that implemented bi-annual high-pressure tube cleaning extended its chiller lifespan by an additional 5 years, saving over $50,000 in replacement costs.

4. Preventing Unexpected Downtime & Costly Repairs

Dirty chiller tubes increase the risk of system failures, causing unexpected shutdowns that can disrupt:

- Manufacturing processes

- Data center cooling

- Hospital and healthcare operations

How High-Pressure Cleaning Ensures Reliability:

- Eliminates debris that could cause blockages and overheating

- Reduces mechanical strain, ensuring consistent performance

- Prevents costly emergency repairs and downtime losses

Unplanned chiller failures in critical industries can result in thousands of dollars in lost productivity per hour.

5. Maintaining Consistent Cooling Performance

Fluctuating temperatures in a chiller system can negatively affect product quality and occupant comfort.

Why High-Pressure Cleaning is Key to Stable Cooling:

- Ensures consistent temperature regulation

- Prevents cold spots or overheating

- Helps HVAC systems maintain peak comfort levels

Who Benefits the Most?

- Pharmaceutical plants (where temperature stability is critical)

- Data centers (where cooling failures can cause server crashes)

- Hotels & office buildings (where guest comfort is a priority)

6.Lowering Overall Operating Costs

Chiller maintenance isn’t just about efficiency—it’s about cost reduction. When tubes are clean:

- The system operates at peak efficiency

- Maintenance costs decrease

- The risk of expensive breakdowns is minimized

Long-Term Financial Benefits:

- Lower energy bills

- Fewer emergency service calls

- Extended equipment lifespan

- Cost-Saving Example:A commercial building that invested in routine high-pressure chiller tube cleaning reduced its annual maintenance expenses by 40% and saved over $75,000 in energy costs.

7.Eco-Friendly & Chemical-Free Cleaning Solution

Unlike some cleaning methods that rely on harsh chemicals, high-pressure water cleaning is a non-toxic, sustainable solution.

Environmental Benefits:

- Uses only water—no harmful chemicals

- Eliminates toxic waste disposal concerns

- Complies with strict environmental standards

Sustainability Factor:

Many companies are now required to meet energy efficiency and environmental compliance goals. High-pressure cleaning helps businesses achieve green certifications and reduce their carbon footprint.

8. Eliminating Bacteria & Health Risks (Including Legionella Prevention)

In HVAC and water-based cooling systems, bacterial growth such as Legionella can develop inside chiller tubes, leading to serious health risks.

High-Pressure Cleaning Protects Public Health:

- Removes biofilm, slime, and bacteria buildup

- Prevents Legionnaires’ disease outbreaks

- Enhances air quality and system hygiene

Facilities must meet ASHRAE 188 standards to prevent Legionella contamination in cooling systems.

9. Ensuring Compliance with Efficiency & Safety Standards

Many industries must comply with government-mandated energy efficiency and equipment safety standards.

High-Pressure Cleaning Helps Meet Regulations Like:

- ASHRAE 90.1 Energy Standards

- EPA Clean Water Act Compliance

- OSHA Equipment Safety Requirements

Failure to maintain chiller efficiency can lead to increased energy costs, compliance fines, and operational inefficiencies.