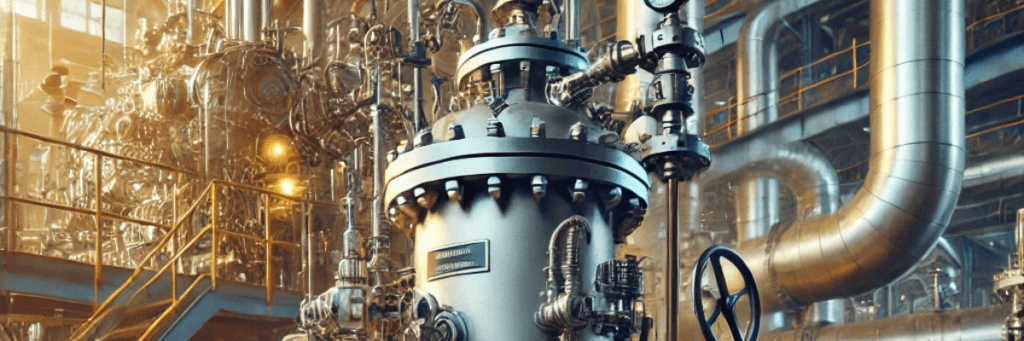

A Boiler Hydro Test Pump is a specialized high-pressure pump used for hydrostatic testing of boilers, pipelines, pressure vessels, and other pressurized equipment. This process involves filling the system with water, increasing pressure to a predetermined level, and assessing structural integrity by checking for leaks or weaknesses. Hydrostatic testing is an essential safety measure required by industry standards such as ASME, API, and ISO to ensure operational reliability

Key Features of Boiler Hydro Test Pumps:

- High-Pressure Capabilities: Designed to generate pressure up to several thousand PSI, depending on the testing requirements.

- Durable Construction: Built with stainless steel or corrosion-resistant materials to withstand high-pressure conditions.

- Portability & Ease of Use: Many models are compact, lightweight, and manually or electrically operated, making them ideal for workshops and on-site testing.

- Safety Mechanisms: Equipped with pressure relief valves and gauge monitors to ensure precise pressure control and avoid overloading.

Applications of Boiler Hydro Test Pumps:

- Boiler Pressure Testing: Boiler hydro test pumps are widely used to verify the strength and integrity of new or repaired boilers. They help detect cracks, leaks, and weak points that could lead to catastrophic failures if left unchecked.

- Pressure Vessel & Storage Tank Testing: Industries such as oil & gas, chemical processing, and power plants use hydrostatic testing to ensure pressure vessels like reactors, storage tanks, and heat exchangers can handle the required pressure levels without failure.

- Pipeline & Piping System Testing: Before commissioning a new pipeline or after conducting repairs, hydro test pumps are used to pressurize pipelines, ensuring they are leak-free and capable of handling operational stress.

- Regulatory Compliance & Safety Assurance:Hydrostatic testing is mandated by international safety codes such as ASME, API, and OSHA. It ensures that boilers, pressure vessels, and piping systems meet strict safety standards before use.

- Routine Maintenance & Inspection: Hydro test pumps are utilized during periodic maintenance of boilers and pressure systems to detect any wear, corrosion, or potential failure points before they become hazardous.

How to Choose the Right Boiler Hydro Test Pump

Selecting the right hydro test pump depends on various factors, including:

- Required Pressure Capacity: Choose a pump that can deliver the necessary PSI or bar pressure.

- Type of System Being Tested: Boilers, pipelines, and pressure vessels may require different testing parameters.

- Mobility Needs: If testing in remote locations, a portable manual pump may be preferred over electric or diesel-powered pumps.

- Compliance Requirements: Ensure the pump meets industry certification standards for your specific application.

Common Issues & Troubleshooting in Hydrostatic Testing

- Pressure Drops During Testing: Could indicate leaks, faulty seals, or inadequate pressure buildup.

- Inconsistent Readings: Check for air pockets in the system or malfunctioning pressure gauges.

- Pump Fails to Build Pressure: InsPump Fails to Build Pressure: Inspect for blockages, worn-out seals, or inadequate water supply.

By using a boiler hydro test pump, engineers and technicians can confirm the structural integrity of a boiler or pressure vessel and ensure it operates safely under high-pressure conditions.