A triplex plunger pump is a type of positive displacement pump that uses three plungers (or pistons) to move fluids at high pressure. It is commonly used in industrial applications such as high-pressure washing, oil and gas drilling, water jetting, and other operations that require a reliable and consistent flow at high pressure. Here’s a detailed explanation of the methods and principles of operation of a triplex plunger pump:

Principle of Operation

The basic principle behind a triplex plunger pump is positive displacement, which means that the pump forces a fixed volume of fluid through a system with each stroke of the plungers. In a triplex pump, there are three plungers working in a sequence, which helps create a steady flow of fluid with minimal pulsation.

Here’s how it works:

- Reciprocating Action: The pump operates through a reciprocating motion. The three plungers (or pistons) move back and forth within cylinders, drawing in fluid during the intake stroke and pushing it out under high pressure during the discharge stroke.

- Positive Displacement: As each plunger moves forward, it displaces a fixed amount of fluid, forcing it into the discharge line. As one plunger is on its discharge stroke, the other two are in different phases of their strokes (either intake or mid-stroke), ensuring continuous flow of fluid.

Methods and Operation Phases

The operation of a triplex plunger pump can be broken down into a series of phases:

1. Intake (Suction) Phase

- As the plunger moves back (away from the discharge valve), a vacuum is created in the cylinder.

- This vacuum opens the suction valve, allowing the fluid to be drawn into the cylinder from the inlet (suction side) of the pump.

- This phase fills the cylinder with fluid in preparation for the discharge phase.

2. Compression Phase

- As the plunger begins to move forward, it compresses the fluid inside the cylinder.

- The suction valve closes due to the increase in pressure inside the cylinder, ensuring no backflow of fluid from the suction side.

- The pressure continues to build as the plunger moves forward, preparing the fluid for high-pressure discharge.

3. Discharge Phase

- Once the plunger moves far enough forward to reach the preset pressure, the discharge valve opens.

- The pressurized fluid is then forced out through the discharge valve into the system or the discharge line.

- The plunger completes its forward stroke, and the cycle repeats.

4. Sequential Operation of Plungers

- In a triplex pump, the three plungers operate at staggered intervals. As one plunger finishes its discharge stroke, the next is in the middle of its compression stroke, and the third is on its intake stroke.

- This sequencing ensures a more consistent flow of fluid with less pulsation compared to single-piston pumps.

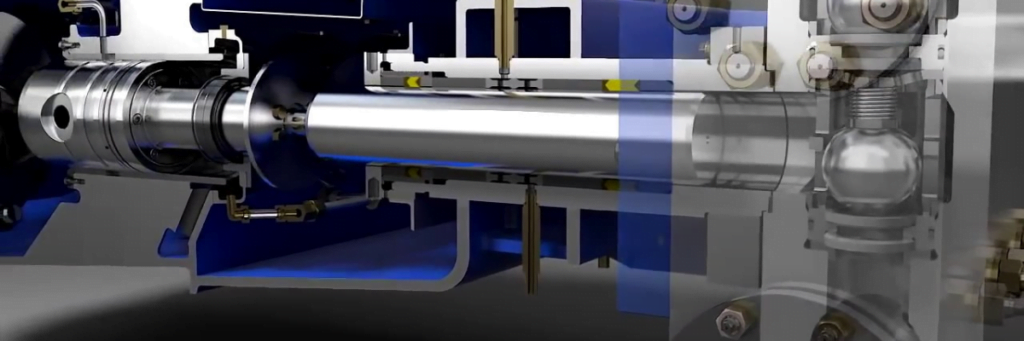

Key Components of a Triplex Plunger Pump

- Plungers (or Pistons): The three plungers move back and forth in a reciprocating motion to draw in and push out fluid. These are the primary moving parts of the pump that create the pumping action.

- Cylinders: Each plunger moves within a cylinder. The cylinder houses the fluid during the intake and compression phases.

- Suction Valve: This valve allows fluid to enter the cylinder during the intake phase. It closes during the compression and discharge phases to prevent fluid from flowing backward into the suction line.

- Discharge Valve: This valve opens when the plunger reaches a certain pressure during the discharge phase, allowing fluid to be forced into the discharge line. It closes during the intake phase to maintain pressure.

- Crankshaft: The crankshaft converts the rotary motion of a motor into the reciprocating motion needed to move the plungers. As the crankshaft rotates, it pushes and pulls the plungers in a coordinated sequence.

- Connecting Rods: These rods connect the crankshaft to the plungers and transfer the motion from the rotating crankshaft to the linear motion of the plungers.

- Pressure Regulators: These devices control and maintain the output pressure, preventing over-pressurization of the system and protecting the pump and connected equipment.

- Packing and Seals: Packing materials are used around the plungers to ensure that fluid doesn’t leak out of the cylinders, and the seals keep the fluid contained within the system.

Performance Characteristics

- High Pressure: Triplex plunger pumps are capable of generating very high pressure, typically up to several thousand PSI (pounds per square inch), making them ideal for applications like high-pressure cleaning, hydrostatic testing, and oilfield services.

- Steady Flow: The three plungers working in sequence provide a more continuous and smooth flow of fluid, reducing pressure pulsations compared to single- or duplex-piston pumps.

- Variable Flow Rate: The flow rate of the pump can be adjusted by controlling the speed of the motor or crankshaft, allowing for flexible operation depending on the application’s requirements.

- Durability: These pumps are built for heavy-duty use and are highly reliable in industries that demand consistent high-pressure fluid movement.

Applications of Triplex Plunger Pumps

- High-Pressure Washing: Used in industrial cleaning for washing equipment, vehicles, and surfaces, especially in industries like construction and transportation.

- Oil and Gas Industry: Utilized in drilling operations, pressure testing, and well servicing where high-pressure fluids are required.

- Water Jetting: Employed for cutting, surface preparation, and cleaning with high-pressure water jets in industries such as shipbuilding, mining, and manufacturing.

- Hydrostatic Testing: Used for pressure testing pipelines, vessels, and tanks to ensure their integrity under high pressure.

- Agricultural Irrigation: Some triplex pumps are used in agricultural applications for high-pressure irrigation systems.

Summary of Operation

- Reciprocating action: The crankshaft rotates, moving the plungers back and forth.

- Sequential movement: The three plungers operate in a phased sequence, ensuring continuous flow and pressure.

- Fluid movement: Each plunger alternately draws in fluid during the intake stroke and forces it out under pressure during the discharge stroke.

- Pressure and flow regulation: Proper valves and regulators ensure consistent output pressure and smooth operation.

In conclusion, triplex plunger pumps are highly efficient, reliable, and capable of delivering high-pressure fluid with a consistent flow, making them a vital component in many industrial operations.