Tube bundles are essential components in heat exchangers, boilers, and condensers across industries such as power plants, chemical processing, oil refineries, and HVAC systems. Over time, these tubes accumulate deposits like scale, sludge, biofilm, and corrosion, reducing heat transfer efficiency and causing operational inefficiencies. High-pressure tube bundle cleaning is a powerful, eco-friendly method to restore performance without damaging the tubes.

Here’s a step-by-step guide on how high-pressure tube bundle cleaning is typically carried out:

1. Pre-Cleaning Inspection & System Preparation

Before starting the high-pressure cleaning process, certain preparations and safety measures are necessary:

- System Shutdown & Isolation: The equipment, such as a heat exchanger, is safely shut down and isolated from the main system.

- Draining & Cooling: Residual fluids or steam are drained, and the unit is allowed to cool to a safe temperature.

- Visual & Technical Inspection: Trained personnel assess the level of fouling using cameras, borescopes, or manual inspection. The type of contamination—scale, sludge, or biological growth—is identified.

- Equipment Setup: High-pressure jetting tools, including specialized nozzles and pumps capable of delivering 5,000 to 40,000 psi, are positioned near the tube bundle.

2. Tube Bundle Positioning & Preparation

Depending on the equipment’s size and structure:

- Tube bundles are removed and transported to a dedicated cleaning area.

- For fixed bundles, in-place cleaning methods are utilized.

3. Selection of Optimal Cleaning Nozzles & Tools

Different contaminants require specific cleaning tools:

- Rotary Nozzles: Ensure 360-degree cleaning inside tubes.

- Lance Nozzles: Used for deeper cleaning inside long tubes.

- Fan Spray Nozzles: Ideal for removing debris from external tube surfaces.

- Automated Cleaning Systems: Improve consistency and safety by using mechanized cleaning lances.

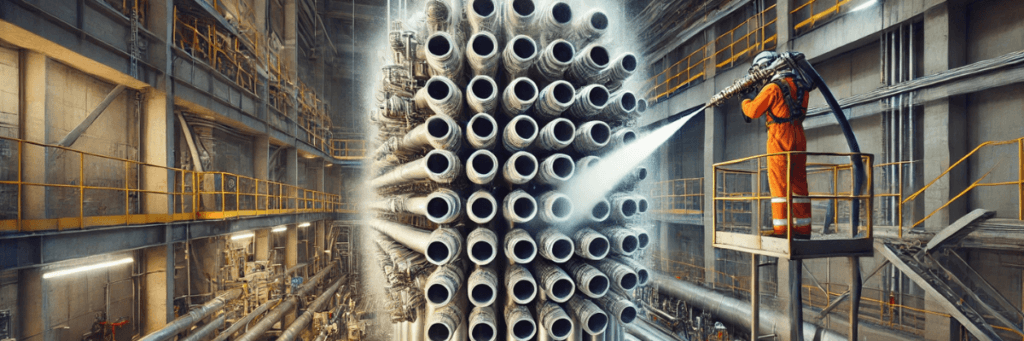

4. Internal High-Pressure Tube Cleaning

- A high-pressure lance is inserted into each tube.

- Water pressure is optimized (typically 10,000–20,000 psi) to avoid tube damage while efficiently removing debris.

- The nozzle moves through the tube’s full length, breaking down deposits and flushing them out.

- Some systems utilize pulsating water jets for improved scale removal.

- Each tube is cleaned individually to ensure complete restoration.

5. External Tube Cleaning for Optimal Performance

- High-pressure fan nozzles remove accumulated contaminants between tubes.

- This step is crucial for maintaining optimal airflow and heat transfer efficiency.

- Cleaning heads are positioned at multiple angles to ensure deep cleaning in tight spaces.

6.Final Rinse & Flushing

- A thorough final rinse with clean water eliminates any residual particles.

- Drainage channels are monitored to ensure com****plete debris removal.

7. Post-Cleaning Quality Check

After cleaning, a detailed inspection ensures all contaminants have been removed:

- Visual Examination: Checks for remaining debris.

- Borescope Inspection: High-resolution cameras verify internal cleanliness.

- Airflow & Fluid Testing: Ensures unrestricted fluid movement.

- If needed, spot-cleaning is performed on any residual fouling.

8. Reinstallation & Performance Testing

- The cleaned tube bundle is reinstalled in its original position.

- The system undergoes pressure and flow rate tests to confirm improved efficiency.

- Final adjustments are made before the unit is returned to full operation.

Why High-Pressure Tube Bundle Cleaning Is Essential

Regular high-pressure cleaning of tube bundles is essential for maintaining system efficiency and performance in industrial applications. Here’s why it is important:

1. Restores Heat Transfer Efficiency

Fouling creates an insulating layer that impairs heat transfer. Removing these deposits significantly enhances energy efficiency and reduces fuel consumption.

2. Prevents Corrosion & Tube Degradation

Accumulated sludge and scale accelerate corrosion and material degradation. Regular cleaning prevents premature failure, saving maintenance and replacement costs.

3. Reduces Downtime & Maintenance Costs

Blocked or inefficient tubes cause overheating and system breakdowns, leading to costly downtimes. High-pressure cleaning ensures reliable, continuous operation.

4. Enhances Overall System Performance

A clean system operates at peak efficiency, reducing operational loads on pumps and fans, lowering energy costs, and boosting production.

5. Eco-Friendly Cleaning Solution

Unlike chemical cleaning methods, high-pressure water jetting eliminates the need for hazardous substances, reducing environmental impact and making it a sustainable solution.