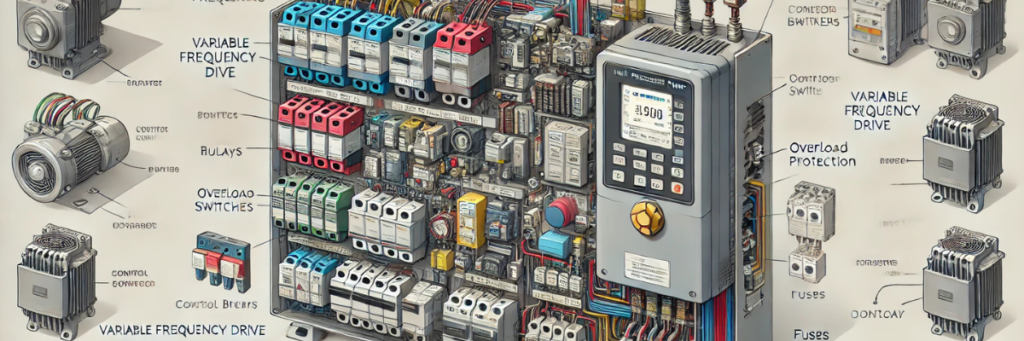

A Variable Frequency Drive (VFD) control panel is essential for managing high-pressure pumps efficiently and ensuring smooth, energy-saving operations. Below is a detailed breakdown of the key components and their functions in a well-designed high-pressure pump VFD control panel.

1. Variable Frequency Drive (VFD)

- Function: Controls motor speed by adjusting the frequency of electrical power.

- Key Features: Overload protection, adjustable speed control, energy efficiency, fault diagnostics.

- Use Case: Prevents motor wear and optimizes energy usage in industries like water treatment, oil & gas, and HVAC systems.

2. Circuit Protection (Breakers & Overload Relays)

- Circuit Breaker:Protects the system from overcurrent and faults

- Overload Relay: Prevents motor overheating and damage

3. Contactors & Control Relays

- Purpose: Manages electrical connection between the VFD and motor for smooth start/stop.

- Automation Role: Enables remote control and can be integrated with PLCs for smart control.

4. Input and Output Filters

- Input Filters: Reduce harmonics and prevent EMI (electromagnetic interference) from power supply.

- Output Filters: Reduce voltage spikes, protecting the motor from damage.

- Best Practices: Use line reactors to further stabilize voltage flow.

5. Control Transformer

- Function: Steps down high voltage for safe operation of control component

- Common Usage: Powers relays, sensors, and communication modules.

- Selection Tip: Choose a shielded transformer for enhanced noise reduction.

6. Cooling & Environmental Control

- Purpose: Protects the motor by disconnecting the circuit when it senses excess current, which could indicate overload conditions.

- Adjustability: Set to the motor’s rated current, providing an additional safety layer for motor protection.

7. Cooling Fans and Heaters

- Cooling Fans: Prevent overheating within the panel due to the heat generated by the VFD and other components.

- Panel Heater: Helps maintain a stable temperature to prevent condensation and potential electrical issues in cooler environments.

8. Human-Machine Interface (HMI) or Display

- Purpose: Displays real-time data such as frequency, voltage, and fault diagnostics.

- Types: Digital LED display or touchscreen interface.

- Enhancement: Use an HMI with alarm indicators for quick troubleshooting.

9. Programmable Logic Controller (PLC) & Smart Control

- PLC Role: Automates pump operation based on sensor feedback.

- Alternative: If a full PLC system is not needed, control relays can handle basic automation.

- Use Case: PLCs in municipal water supply systems ensure steady pressure levels.

10. Current and Voltage Sensors

- Current Transformer (CT): Measures the current flowing to the motor to monitor and protect against overcurrent conditions.

- Voltage Sensor: Monitors voltage levels to ensure stable operation and prevent issues from voltage fluctuations.

11. Safety & Protection Mechanisms

- Emergency Stop Button: Provides an instant shutdown for safety compliance.

- Surge Protection Device (SPD): Protects against power surges and spikes.

- Enclosure Design: Ensure IP-rated enclosures for dust and water protection

12. Surge Protection Device (SPD)

- Function: Protects the VFD and other sensitive components from power surges and spikes that could damage the system.

13. Wiring and Terminal Blocks

- Terminal Blocks: Used for organized connections and easy maintenance of power, control, and communication lines.

- Quality Wiring: Essential for minimizing voltage drops and ensuring safety and efficiency.

Optional Components

- Communication Modules: For remote monitoring and control via protocols like Modbus, Ethernet, or Profibus.

- Battery Backup (UPS): Provides temporary power during outages, allowing for safe shutdown of the system.

A well-designed high-pressure pump VFD control panel with these components will provide efficient control, protection, and operational flexibility, making it essential for applications requiring reliable high-pressure pumping.