Pumps can be classified by the pressure they generate during operation. This classification is essential because different applications require varying levels of pressure, depending on the nature of the fluid being moved and the system requirements. Here’s a classification of pumps based on their pressure range:

1. Low-Pressure Pumps

- Pressure Range: Up to 150 psi (10 bar)

- Common Applications:

- Water circulation (e.g., in heating and cooling systems)

- Irrigation systems

- Domestic water supply (e.g., boosting pressure in homes)

- Low-pressure filtration systems

- Aquarium and pond pumps

- Types of Pumps:

- Centrifugal pumps: Widely used in low-pressure applications due to their ability to handle large volumes of liquid at relatively low pressures.

- Submersible pumps: Used in wells and sump pumps for water extraction.

- Diaphragm pumps: Often used in low-pressure applications such as small-scale fluid transfer or dosing.

- Examples:

- End-suction centrifugal pumps used for water distribution

- Peripheral pumps for small-scale water circulation

2. Medium-Pressure Pumps

- Pressure Range: Between 150 to 650 psi (10 to 45 bar)

- Common Applications:

- Municipal water distribution

- Boiler feed pumps (in smaller systems)

- Firefighting systems

- Hydraulic systems

- Process water systems in industrial plants

- Types of Pumps:

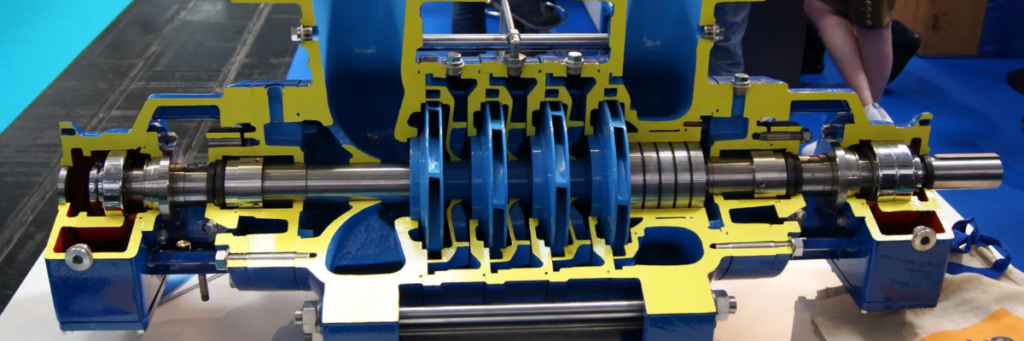

- Multistage centrifugal pumps: Designed to achieve higher pressure by using multiple impellers in series.

- Gear pumps: Used in hydraulic applications where moderate pressures are needed.

- Piston pumps: Provide moderate pressure for fluid transfer and power washing applications.

- Examples:

- Vertical multistage pumps used in industrial water supply systems.

- Hydraulic gear pumps for mobile or stationary hydraulic systems.

3. High-Pressure Pumps

- Pressure Range: Between 650 to 2,000 psi (45 to 140 bar)

- Common Applications:

- Reverse osmosis (RO) systems (for water desalination and filtration)

- High-pressure washing systems (e.g., car washes, industrial cleaning)

- Boiler feed pumps in power plants

- Hydraulic power units

- Industrial process applications (e.g., in chemical plants and refineries)

- Types of Pumps:

- Triplex plunger pumps: Common in high-pressure water jetting, cleaning, and oil and gas applications.

- High-pressure multistage pumps: Used in high-pressure applications like boiler feed systems or process water.

- Axial piston pumps: Used in high-pressure hydraulic systems.

- Examples:

- Plunger pumps used in pressure washers and RO systems.

- Multistage centrifugal pumps for industrial fluid handling.

4. Ultra-High-Pressure Pumps

- Pressure Range: Above 2,000 psi (140 bar), often reaching up to 40,000 psi (2,750 bar) in specialized applications

- Common Applications:

- Water jet cutting (in industrial manufacturing)

- High-pressure cleaning (for removing coatings, rust, and concrete)

- Oil and gas production (for injection and fracking)

- Hydraulic press systems

- Descaling systems (for cleaning metal surfaces in steel production)

- Hyperbaric testing systems (to simulate deep-sea pressure environments)

- Types of Pumps:

- Intensifier pumps: Used in waterjet cutting systems to generate extremely high pressures.

- Reciprocating plunger pumps: Commonly used in ultra-high-pressure cleaning, testing, and hydraulic fracturing (fracking).

- Hydraulic piston pumps: Used in ultra-high-pressure hydraulic systems.

- Examples:

- Waterjet pumps for precision cutting of materials like metal, glass, and stone.

- Hydraulic fracturing pumps in oilfield operations.

Summary Table

| Pressure Classification | Pressure Range (psi) | Common Applications | Pump Types |

|---|---|---|---|

| Low-Pressure Pumps | Up to 150 psi | Domestic water supply, irrigation, circulation | Centrifugal, diaphragm, submersible, peripheral |

| Medium-Pressure Pumps | 150 to 650 psi | Municipal water distribution, firefighting, hydraulic systems | Multistage centrifugal, gear, piston |

| High-Pressure Pumps | 650 to 2,000 psi | RO systems, industrial cleaning, boiler feed | Triplex plunger, high-pressure multistage, axial piston |

| Ultra-High-Pressure Pumps | Above 2,000 psi | Water jet cutting, oil & gas, descaling, hyperbaric testing | Intensifier, reciprocating plunger, hydraulic piston |

Factors to Consider When Selecting a Pump by Pressure:

- Application Requirements: The type of fluid being pumped and the nature of the application (clean water, slurry, chemicals, oil, etc.) will dictate the pressure needed.

- Flow Rate: The flow rate in combination with pressure is crucial in pump selection. Higher pressure may reduce the required flow rate, and vice versa.

- Efficiency: Higher pressure pumps may require more energy. Balancing pressure and efficiency is important for operational cost considerations.

- Pump Type: Different types of pumps (centrifugal, plunger, diaphragm, etc.) are optimized for specific pressure ranges. Choose the type that best suits the pressure requirements of your application.

- Material of Construction: High-pressure applications often require materials that can withstand significant forces and potential corrosion or wear, such as stainless steel or high-strength alloys.

Conclusion

The classification of pumps by pressure provides a framework for choosing the right pump for specific applications. From low-pressure systems used in domestic and light industrial applications to ultra-high-pressure pumps used in specialized industrial processes, understanding the required pressure helps ensure optimal pump performance and reliability in a given application.