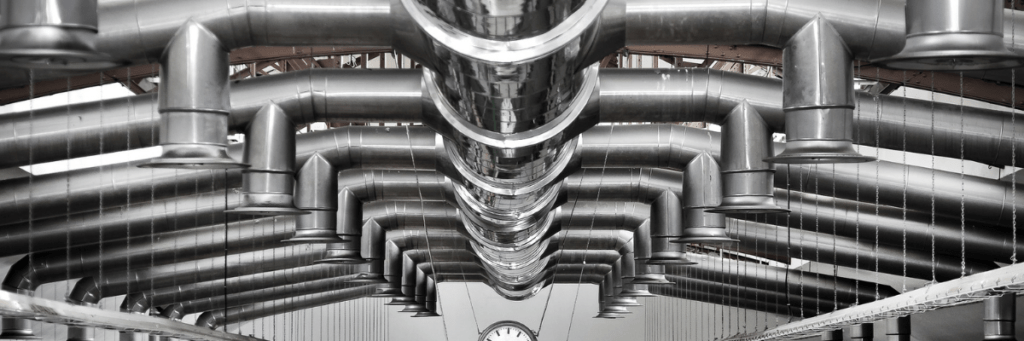

High-pressure washing of exhaust and ventilation systems offers numerous advantages, especially in industrial, commercial, and residential settings. These systems are crucial for maintaining air quality and ensuring the safe operation of buildings and facilities, but they can accumulate grease, dust, debris, and other contaminants over time. High-pressure washing is an effective solution to clean these systems thoroughly. Below are the key advantages of high-pressure washing for exhaust and ventilation systems:

1. Improved Air Quality

- Advantage: High-pressure washing removes accumulated dust, dirt, and contaminants from ventilation ducts, exhaust fans, and filters, improving the overall air quality within the facility.

- Benefit: Clean ventilation systems circulate cleaner, healthier air, which is critical for maintaining the health and comfort of building occupants. This is particularly important in environments like hospitals, schools, and workplaces where air quality directly impacts well-being and productivity.

2. Increased Energy Efficiency

- Advantage: Dirty exhaust and ventilation systems force HVAC units and fans to work harder to maintain airflow, leading to higher energy consumption. High-pressure cleaning removes debris and blockages, restoring optimal airflow.

- Benefit: By improving airflow, high-pressure cleaning reduces the energy required for heating, cooling, and ventilation, leading to lower energy bills and reducing the facility’s carbon footprint.

3. Prevention of Fire Hazards

- Advantage: In kitchens, restaurants, and industrial facilities, grease and flammable particles can accumulate in exhaust systems, increasing the risk of fire. High-pressure washing effectively removes these flammable deposits.

- Benefit: Regular cleaning of exhaust systems reduces fire hazards, making the environment safer for workers and preventing costly damages. This is particularly critical in kitchens and industrial settings where grease buildup is common.

4. Extended Equipment Lifespan

- Advantage: High-pressure washing removes debris, dust, and contaminants that can cause wear and tear on ventilation and exhaust system components, such as fans, filters, and ducts.

- Benefit: Clean systems operate more efficiently and experience less strain, which can extend the life of the equipment. This reduces the frequency of repairs and replacements, leading to long-term cost savings.

5. Compliance with Health and Safety Regulations

- Advantage: Many industries, such as food processing, healthcare, and manufacturing, must adhere to strict regulations regarding air quality, cleanliness, and safety. High-pressure washing ensures that exhaust and ventilation systems meet these standards.

- Benefit: Regular cleaning helps facilities maintain compliance with local and national health and safety codes, avoiding fines, legal issues, and potential business closures due to non-compliance.

6. Reduction of Odors

- Advantage: Over time, exhaust and ventilation systems can trap unpleasant odors from cooking, industrial processes, or chemical use. High-pressure washing removes the buildup of odor-causing contaminants.

- Benefit: Clean systems help eliminate lingering odors, improving the environment for building occupants and enhancing customer satisfaction in commercial settings like restaurants and hotels.

7. Improved System Performance

- Advantage: When ventilation and exhaust systems are clogged with dust, debris, or grease, their performance diminishes, leading to reduced airflow and inefficient operation. High-pressure washing restores system performance by thoroughly cleaning ducts and fans.

- Benefit: Improved airflow ensures that systems operate at peak efficiency, reducing operational costs and ensuring better temperature control, ventilation, and exhaust management within the facility.

8. Reduction of Allergen and Pollutant Buildup

- Advantage: Dust, mold spores, pollen, and other allergens can accumulate in ventilation systems, leading to poor indoor air quality and potential health issues for building occupants. High-pressure washing removes these contaminants from the system.

- Benefit: Reducing allergen buildup helps create a healthier environment, particularly in settings like office buildings, schools, and healthcare facilities, where air quality is essential for occupants’ comfort and well-being.

9. Minimized Downtime

- Advantage: High-pressure washing is an efficient method for cleaning exhaust and ventilation systems compared to manual cleaning or less effective techniques.

- Benefit: Faster and more thorough cleaning means less downtime for businesses and industrial operations, allowing for minimal disruption to daily activities and reducing the time needed for maintenance.

10. Non-Chemical and Environmentally Friendly Cleaning

- Advantage: High-pressure washing uses water, often without the need for harsh chemicals, to clean ventilation and exhaust systems.

- Benefit: This method is environmentally friendly, reducing chemical exposure and pollution. It is also safer for workers, as they are not exposed to potentially harmful cleaning agents, making it a sustainable and safe cleaning option.

11. Prevents Corrosion and Deterioration

- Advantage: Dust, grease, and chemical residues in ventilation and exhaust systems can lead to corrosion or damage to ducts and metal components over time. High-pressure washing removes corrosive materials, protecting the system.

- Benefit: Regular cleaning helps prevent rust and deterioration of system components, thus avoiding costly repairs and replacements, while maintaining system integrity over the long term.

Conclusion

High-pressure washing of exhaust and ventilation systems provides numerous benefits, including improved air quality, enhanced energy efficiency, reduced fire risks, and extended equipment life. By removing accumulated dirt, debris, grease, and contaminants, this method ensures the optimal performance of ventilation systems, improves safety, and helps industries comply with health and safety regulations. Additionally, high-pressure washing is an eco-friendly, efficient, and cost-effective solution for maintaining clean and functional exhaust and ventilation systems in various industries.