What is an Evaporator Tube?

Evaporator tubes are essential components in industrial evaporators, which convert liquids into vapor through the application of heat. These tubes are found in various industries, including power generation, food processing, chemical manufacturing, refrigeration, and HVAC systems.

Typically constructed from stainless steel, copper, or corrosion-resistant alloys, evaporator tubes facilitate heat transfer, ensuring efficient evaporation of substances such as water, refrigerants, or chemical solutions.

How Do Evaporator Tubes Work?

In an evaporator system:

- A liquid (e.g., water or refrigerant) passes through the tubes.

- Heat is applied externally or through indirect heat exchange.

- The liquid inside the tube absorbs heat, turns into vapor, and exits the system.

This process is vital for applications like steam production, refrigeration cycles, and chemical purification. However, over time, the tubes accumulate scale, fouling, and deposits, which compromise efficiency and performance. This is where high-pressure cleaning becomes a game-changer.

Why High-Pressure Cleaning is Important for Evaporator Tubes

High-pressure cleaning is essential for maintaining the efficiency, safety, and longevity of evaporator tubes. Here’s why it is so important:

1. Eliminating Scale and Deposits for Maximum Efficiency:

Evaporator tubes are prone to mineral buildup, including:

- Calcium and magnesium deposits

- Salt accumulations

- Rust and corrosion residues

- Biological contaminants (such as bacterial growth in food and pharmaceutical industries)

These insulating layers reduce heat transfer efficiency, making the system work harder and consume more energy. High-pressure water jets effectively break down and remove these stubborn deposits, restoring evaporator tubes to optimal performance levels.

2. Enhancing Heat Transfer for Lower Energy Costs:

As deposits accumulate, they create a barrier between the heat source and the liquid inside the tubes. This means:

- More energy is required to achieve the same evaporation levels.

- Higher operational costs due to increased fuel or electricity consumption.

- Reduced output and productivity.

With high-pressure cleaning, heat transfer surfaces are restored, improving thermal efficiency and minimizing operational expenses.

3. Preventing Costly Tube Failures and Downtime:

if evaporator tubes remain uncleaned, excessive scaling can lead to:

- Localized overheating, weakening the tube walls.

- Corrosion damage, causing leaks or ruptures.

- Complete system failure, resulting in expensive repairs and production downtime.

Regular high-pressure cleaning prevents tube failure, ensuring reliable system operation and reducing maintenance expenses.

4. Ensuring Contamination-Free Processing in Sensitive Industries:

For industries such as food processing, pharmaceuticals, and chemical manufacturing, contaminated evaporator tubes can:

- Introduce harmful bacteria or residues into final products.

- Alter chemical purity, affecting drug formulation.

- Compromise food safety standards.

Using high-pressure water jets, industries can ensure hygienic, contamination-free operation, preserving product integrity and regulatory compliance.

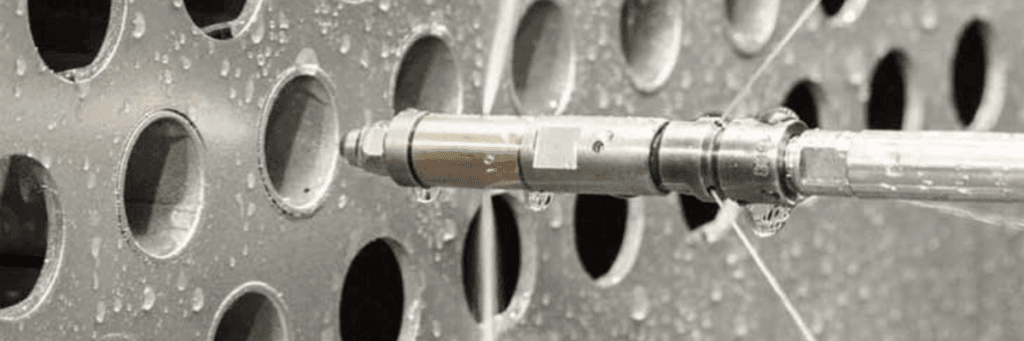

5. Faster, More Effective Cleaning Without Disassembly:

Unlike manual cleaning or chemical descaling, which often require system downtime, high-pressure cleaning:

- Cleans multiple tubes simultaneously without disassembly.

- Completes the process more quickly than traditional methods.

- Reduces labor-intensive scrubbing and chemical handling risks.

This ensures that industrial systems return to full operation swiftly, improving overall productivity.

6. An Eco-Friendly, Non-Corrosive Alternative to Harsh Chemicals:

Many traditional cleaning methods rely on acidic or alkaline chemical solutions to dissolve deposits. However, these chemicals:

- Pose environmental hazards.

- Risk equipment corrosion.

- Require special handling and disposal procedures.

High-pressure water jet cleaning offers a chemical-free, eco-friendly alternative, preserving tube longevity while reducing environmental impact.

7. Preserving Equipment Lifespan Without Abrasive Damage:

Unlike mechanical cleaning methods, high-pressure water cleaning:

- Does not scratch, erode, or weaken tube surfaces.

- Prevents material degradation, ensuring longer equipment lifespan.

- Maintains structural integrity, reducing the risk of premature failures.

This makes it the preferred cleaning method for delicate yet critical industrial components.

8. Customizable Cleaning Pressure for Different Applications:

Not all deposits require the same cleaning intensity. High-pressure pumps can be adjusted to:

- Low pressure – for gentle cleaning of delicate or thin-walled tubes.

- Ultra-high pressure – for removing stubborn scale or rust deposits.

This adaptability ensures that evaporator tubes remain undamaged while achieving thorough cleaning.

Industries Benefiting from High-Pressure Cleaning of Evaporator Tubes:

- Power Generation: Ensures efficient steam production and prevents power plant downtime.

- Food & Beverage Processing: Maintains purity and hygiene for food-grade processing.

- Chemical & Pharmaceutical Industries: Prevents cross-contamination in chemical synthesis and drug manufacturing.

- Refrigeration & HVAC Systems: Improves cooling efficiency and extends the life of refrigeration units.