What is a Condenser Tube and How Ultra-High-Pressure Pumps Keep It Spotless?

Understanding Condenser Tubes: Function and Importance

A condenser tube is a vital component in heat exchange systems found in industries such as power plants, refineries, HVAC (Heating, Ventilation, and Air Conditioning), and marine engineering. These tubes facilitate the condensation of steam or gas back into liquid form by efficiently transferring heat away from the system.

Condenser tubes are commonly made from copper alloys, stainless steel, titanium, and corrosion-resistant materials to withstand extreme temperatures, high pressure, and exposure to cooling fluids. However, due to continuous contact with minerals, biological contaminants, and scaling deposits, these tubes often develop stains, fouling, and blockages, significantly reducing heat transfer efficiency and increasing energy consumption.

Challenges in Condenser Tube Maintenance

Over time, condenser tubes accumulate calcium deposits, limescale, biofilms, rust, and other contaminants, leading to:

- Reduced heat exchange efficiency – leading to higher energy consumption.

- System overheating and inefficiency – affecting power generation and industrial cooling.

- Corrosion and premature failure – resulting in expensive repairs and replacements.

To ensure optimal performance, regular maintenance and cleaning of condenser tubes is crucial. This is where ultra-high-pressure (UHP) pumps play a game-changing role.

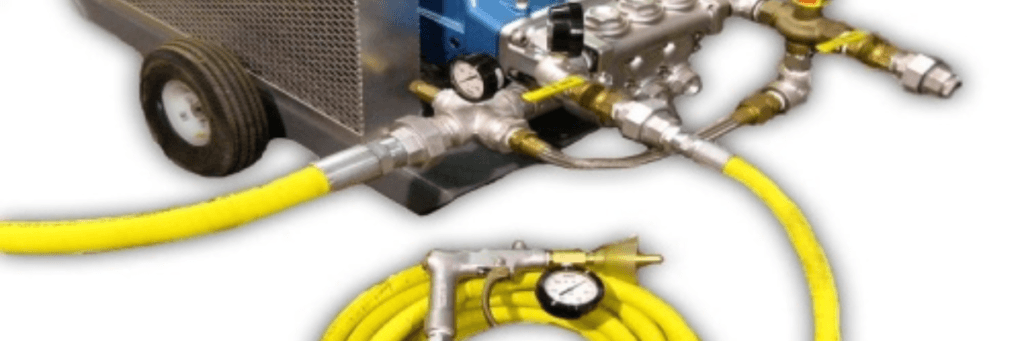

How Ultra-High-Pressure Pumps Keep Condenser Tubes Stain-Free

1. Unmatched Cleaning Power:

Ultra-high-pressure pumps generate intensely pressurized water jets ranging from 1,400 bar (20,000 psi) to over 2,800 bar (40,000 psi). This force effectively breaks down and removes even the toughest scaling deposits, calcium buildup, rust, and biofilms from the internal surfaces of condenser tubes without causing damage.Unlike mechanical cleaning methods, UHP prevents tube erosion while offering superior efficiency in contaminant removal.

2. Eco-Friendly, Chemical-Free Cleaning:

Conventional cleaning methods rely on chemical solutions that may be hazardous to equipment, personnel, and the environment. UHP cleaning eliminates the need for harsh chemicals, using only high-pressure water to achieve deep cleaning results.

- No toxic residues left behind.

- No chemical disposal costs.

- Environmentally sustainable approach for industries prioritizing green practices.

3. Precision Cleaning for Hard-to-Reach Areas:

Ultra-high-pressure cleaning systems use specialized rotating nozzles that ensure 360-degree coverage inside condenser tubes. This method effectively reaches bends, corners, and narrow sections, which are typically difficult to clean with manual or traditional cleaning techniques.This ensures every inch of the condenser tube is free from blockages and contaminants, restoring peak efficiency.

4. Faster and More Cost-Effective Maintenance:

Time is money in industrial operations. UHP cleaning is significantly faster than conventional cleaning methods, meaning:

- Reduced downtime for equipment

- Lower maintenance costs due to fewer manual labor requirements.

Longer intervals between cleanings, as UHP ensures a more thorough removal of contaminants.

5. Prevents Corrosion and Extends Tube Lifespan:

Deposits such as salt, biofilms, and scale not only reduce heat transfer but also accelerate corrosion, leading to costly tube failures. Regular UHP cleaning prevents corrosion by ensuring no foreign substances remain inside the tubes, thereby extending their operational lifespan.Less corrosion = Fewer replacements and long-term cost savings.

6. Maximizing Energy Efficiency:

Clean condenser tubes directly improve the efficiency of heat exchangers and cooling systems. When fouling and deposits are removed, the system requires less energy to maintain optimal performance.Lower operational costs and improved energy efficiency lead to significant savings for power plants, refineries, and HVAC systems.

7. Safe, Non-Abrasive Cleaning Method:

Mechanical cleaning methods such as wire brushing or chemical descaling can damage delicate tube materials. Ultra-high-pressure water jetting, when used with the correct nozzle and pressure settings, ensures that tubes remain structurally intact while achieving deep cleaning.Ideal for cleaning sensitive equipment used in industrial and marine applications.

Applications of Ultra-High-Pressure Pumps for Condenser Tube Cleaning:

- Power Plants: In steam turbines, where large volumes of steam need to be condensed efficiently, UHP pumps are used to keep condenser tubes free from mineral deposits and scaling, ensuring optimal performance.

- Refineries and Petrochemical Plants: These facilities use condenser systems in their processes, and UHP cleaning helps to remove fouling that forms due to exposure to various chemicals and cooling water.

- HVAC Systems: Large-scale air conditioning and refrigeration systems often use condensers, and UHP pumps are used to keep the tubes clean and functioning efficiently.

- Marine Industry: Condenser systems in ships and marine environments often face scaling and fouling from saltwater, and ultra-high-pressure water jetting is the preferred method for removing these deposits.