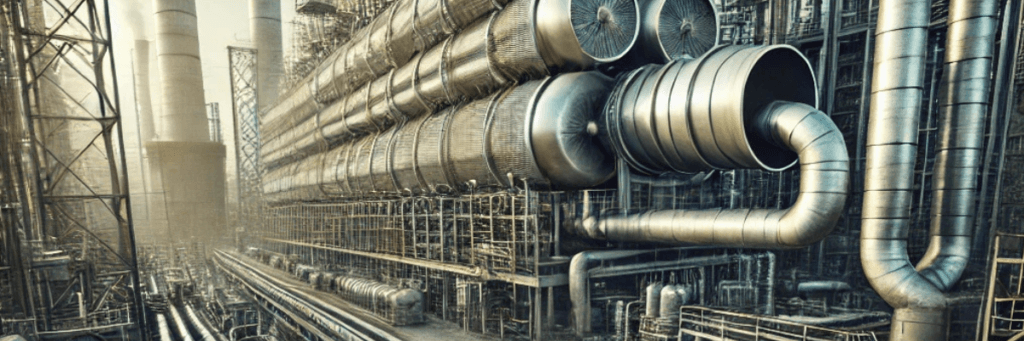

Understanding ACC Tubes in Power Plants

Air-Cooled Condensers (ACC) play a crucial role in power plants by condensing steam from the turbine exhaust back into water, enabling a closed-loop system that reduces reliance on external water sources. This is particularly beneficial in regions facing water scarcity or stringent environmental regulations.

At the core of this system are ACC tubes, which act as heat exchangers, transferring steam heat to the air for condensation. Over time, these tubes accumulate dust, dirt, and airborne contaminants, diminishing heat transfer efficiency and leading to higher turbine backpressure, increased fuel consumption, and overall reduced plant efficiency.

To combat these issues, power plants rely on high-pressure water jet cleaning, a proven method for restoring optimal performance and ensuring long-term operational reliability.

High-Pressure Cleaning Process for ACC Tubes in Power Plants

1. Preparing the ACC Tubes for Cleaning

Before initiating the cleaning process, the ACC system is partially or fully isolated to ensure safe operations. Depending on plant requirements, this may involve temporary shutdowns or selective system isolation.

Preliminary manual cleaning is performed to remove larger debris, such as leaves, paper, or foreign objects lodged around the ACC tube bundles. This step ensures that high-pressure cleaning focuses on the more stubborn layers of dirt and particulate deposits.

2. Application of High-Pressure Water Jet Cleaning

High-pressure water jets are directed at the external surfaces of the ACC tubes using specialized cleaning nozzles. The pressure typically ranges from 100 to 350 bar (1500 to 5000 psi), adjusted based on the severity of the fouling and the material composition of the tubes.

- Rotary nozzles ensure uniform coverage across tube surfaces.

- Fan nozzles optimize water spread to penetrate contaminants between the tube fins.

- Long-reach lances allow access to hard-to-reach areas within the ACC bundle.

The high-impact water jet dislodges accumulated dust, dirt, and contaminants without damaging the sensitive tube fins, restoring optimal heat transfer efficiency.

3. Specialized Cleaning for Finned Surfaces

- ACC tubes feature finned surfaces to enhance heat dissipation. However, these fins trap dust and dirt, which restricts airflow and reduces efficiency.

- High-pressure cleaning is highly effective for removing deposits from between these fins, thanks to precision-engineered nozzles designed to penetrate narrow spaces. In cases where deep contamination persists, specialized cleaning attachments are used to ensure complete removal without fin damage.

4. Eco-Friendly Cleaning Without Chemicals

- Unlike conventional cleaning techniques that involve harsh solvents, high-pressure cleaning relies solely on water, making it a non-toxic and environmentally friendly solution. This eliminates concerns over chemical waste disposal and regulatory compliance.

- Furthermore, this method is non-abrasive, preserving the structural integrity of ACC tube fins and surfaces, reducing long-term maintenance costs.

5. Post-Cleaning Inspection & Maintenance

Once cleaning is complete, detailed inspections are conducted to ensure all contaminants have been removed. This step includes:

- Visual examination to confirm cleanliness.

- Thermal imaging to detect residual fouling.

- Structural integrity checks to identify any signs of tube wear, corrosion, or leaks.

Regular post-cleaning inspections enable early detection of potential maintenance issues, helping power plants implement preventive strategies before failures occur.

The Importance of Regular High-Pressure Cleaning for ACC Tubes

Regular high-pressure cleaning of ACC tubes is essential for maintaining the performance and efficiency of power plants. Here are the key reasons why this process is so important:

1. Restoring Heat Transfer Efficiency

A layer of dirt and particulate buildup on ACC tubes acts as an insulator, significantly reducing the rate of heat transfer. This means that steam does not condense efficiently, leading to higher backpressure and reduced turbine performance. High-pressure cleaning removes these contaminants, restoring efficient steam condensation and optimizing plant operations.

2. Reducing Turbine Backpressure and Enhancing Performance

Dirty ACC tubes increase turbine backpressure, which forces the system to work harder, reducing overall energy conversion efficiency. By regularly cleaning ACC tubes, plants can lower backpressure, enabling turbines to operate at peak efficiency, reducing wear and improving longevity.

3. Lowering Fuel Consumption and Operational Costs

Fouled ACC tubes lead to higher fuel consumption, as more energy is required to compensate for reduced heat rejection. Cleaning ACC tubes restores efficiency, enabling plants to use less fuel per unit of power generated, thereby reducing operational costs and increasing profitability.

4. Extending the Lifespan of ACC Tubes and Fins

Accumulated contaminants can accelerate corrosion and mechanical wear, particularly when dust traps moisture. High-pressure cleaning removes corrosive residues, preventing long-term damage and extending the operational life of ACC components.

5. Reducing Unplanned Downtime and Maintenance Costs

Failure to clean ACC tubes regularly can lead to unexpected performance drops, forcing plants to schedule emergency shutdowns for maintenance. Implementing a proactive cleaning strategy ensures steady plant operations, reducing downtime and avoiding costly emergency repairs.

6. Environmental Compliance and Sustainability

Power plants must comply with strict environmental regulations, particularly concerning emissions and cooling efficiency. High-pressure cleaning minimizes energy wastage and supports sustainable power generation by improving system efficiency and reducing the plant’s carbon footprint.