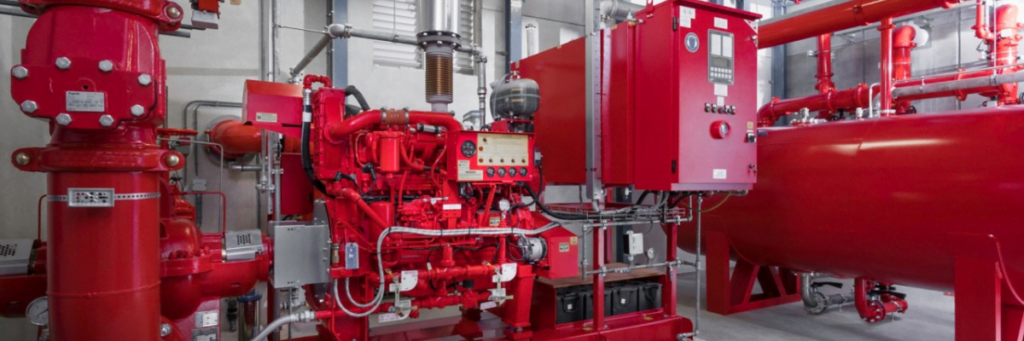

A fire proof pump (or fire-resistant pump) is designed to operate in high-temperature and fire-prone environments, such as industrial plants, refineries, offshore oil rigs, and critical infrastructure where fire risks are high. These pumps are engineered to continue functioning even during extreme fire conditions, ensuring the delivery of critical services like water, fuel, or other necessary fluids during emergencies.

How Fireproof Pumps Work

- Construction and Materials:

- Fireproof pumps are constructed from high-temperature resistant materials such as cast iron, stainless steel, or special alloys that can withstand prolonged exposure to heat and flames without losing their structural integrity.

- Seals and gaskets are made of fire-resistant materials like graphite or other high-temperature elastomers to prevent leakage in extreme conditions.

- Motor casings and electrical components are often designed with fire-resistant enclosures to prevent damage to critical components during a fire.

- Cooling Systems:

- Some fireproof pumps are equipped with self-contained cooling systems that prevent overheating during extreme heat exposure. This ensures that the pump’s motor and other critical components do not fail when exposed to high temperatures.

- In certain designs, thermal barriers or jackets are used to insulate critical components from the heat.

- Continuous Operation:

- These pumps are designed to operate continuously, even when exposed to fire. They are often used in firefighting applications or safety-critical processes where maintaining a constant flow of water or other fluids is necessary to suppress fires or control dangerous substances.

- Backup power systems or battery-operated motors are often incorporated into fireproof pumps, allowing them to function independently of external power sources, especially if the main power supply is compromised by fire.

- Explosion-Proof Features:

- In environments where flammable liquids or gases are present (such as oil and gas refineries), fireproof pumps often incorporate explosion-proof features. These designs prevent sparks or heat from igniting volatile materials in the surrounding environment, ensuring safety during both normal operations and fire emergencies.

- Fire Detection and Automatic Activation:

- Many fireproof pumps are integrated into fire detection and suppression systems, allowing them to be automatically activated when a fire is detected. This is particularly important for firewater pumps in industrial plants, which automatically deliver large volumes of water to combat fires.

- In some cases, the pumps are linked to thermal sensors or fire alarms that trigger the pump’s operation, ensuring immediate response to fire emergencies.

Importance of Fireproof Pumps

- Ensures Safety During Fire Emergencies:

- Fireproof pumps are crucial in maintaining the flow of critical resources (such as water or firefighting foam) during emergencies, helping to suppress fires and control their spread.

- For facilities like chemical plants, refineries, power plants, and offshore platforms, where fire risks are high, these pumps help minimize the potential for catastrophic damage by ensuring that firefighting systems remain operational under extreme heat conditions.

- Protection of Critical Infrastructure:

- In refineries, petrochemical plants, and power generation facilities, fireproof pumps are critical for maintaining cooling systems, fuel circulation, and lubrication for machinery that could overheat or malfunction during a fire.

- By ensuring that essential systems continue to function, fireproof pumps protect critical infrastructure from long-term damage, reducing the risk of costly repairs, downtime, or even catastrophic failure.

- Compliance with Fire Safety Regulations:

- Many industrial operations are subject to stringent fire safety regulations, particularly in hazardous industries like oil and gas, chemicals, and pharmaceuticals. Installing fireproof pumps helps facilities comply with international fire safety standards (such as NFPA 20, which governs fire pump installations), reducing legal risks and improving operational safety.

- Compliance with these standards is necessary for obtaining insurance coverage and avoiding fines or shutdowns.

- Minimizes Loss of Life and Property:

- Fireproof pumps are essential in high-risk environments where flammable materials are stored or processed. By providing a reliable source of fire suppression, these pumps help prevent the spread of fires, reducing the potential for loss of life and property damage.

- In emergency situations, having a functioning fireproof pump can mean the difference between a controlled fire and a devastating catastrophe.

- Ensures Continuity of Operations:

- In facilities where continuous operation is critical (such as power plants or data centers), fireproof pumps ensure that systems like cooling water circulation or fire suppression systems continue to operate during a fire, preventing total system failure.

- This is especially important in mission-critical industries where any downtime could lead to significant financial losses or impact public safety.

- Reduces Environmental Impact:

- In environments dealing with hazardous or environmentally sensitive materials, fireproof pumps can help prevent the release of harmful substances into the environment during a fire. By keeping cooling or containment systems operational, they can limit the spread of dangerous chemicals or flammable liquids, minimizing environmental contamination.

- Automatic Fire Suppression:

- Fireproof pumps often form part of a larger automatic fire suppression system. These pumps are responsible for delivering water, foam, or other fire retardants to sprinkler systems or hose reels, ensuring that fires are controlled quickly, even in the absence of manual intervention.

- Automatic activation of fireproof pumps can prevent small fires from escalating into large-scale emergencies, providing early and efficient fire control.

Key Applications of Fireproof Pumps

- Fire Fighting Systems:

- Firewater pumps are used in industrial firefighting systems to deliver high-pressure water for extinguishing fires.

- Sprinkler systems in commercial and residential buildings also use fireproof pumps to ensure the supply of water during fire emergencies.

- Oil and Gas Industry:

- Fireproof pumps are critical in refineries, oil platforms, and petrochemical plants, where flammable liquids and gases pose a constant fire risk. These pumps provide the necessary fire suppression, cooling, and containment during emergencies.

- Power Plants:

- In power generation facilities, fireproof pumps ensure the continuous operation of cooling systems and fire suppression systems to prevent overheating or damage to turbines, generators, and other critical equipment.

- Chemical Plants:

- Fireproof pumps are used in chemical processing plants to manage flammable materials, ensuring that fire suppression systems remain operational during a fire and preventing the spread of hazardous chemicals.

- Data Centers:

- In data centers, fireproof pumps are part of the critical infrastructure that supports cooling systems and fire suppression to protect sensitive equipment from overheating or fire damage.

Conclusion

A fireproof pump is an essential component in high-risk environments, designed to withstand extreme heat and continue operating during fire emergencies. By ensuring the continued delivery of water or other firefighting agents, fireproof pumps play a crucial role in protecting human lives, valuable assets, and infrastructure. Their importance is evident in industries such as oil and gas, chemical processing, and power generation, where fire risks are high, and quick, reliable fire suppression is necessary to prevent catastrophic damage.