High-pressure cleaning systems play a crucial role in maintaining the efficiency and performance of conveyor systems across a variety of industries, including manufacturing, mining, food processing, and logistics. Conveyor systems can accumulate dirt, debris, and product residues over time, which can affect their operation, lead to equipment failure, and even pose safety risks. Below are the key applications of high-pressure cleaning in conveyor systems:

1. Removing Dirt and Debris from Conveyor Belts

- Application: Conveyor belts, especially in industries like mining, agriculture, and construction, can accumulate dirt, mud, sand, and debris. High-pressure cleaning systems are used to remove these contaminants from the surface of the conveyor belt.

- Benefit: Clean conveyor belts ensure smooth material flow and reduce wear on the belt and drive systems. Regular cleaning also minimizes belt misalignment caused by the buildup of dirt and debris, reducing maintenance costs and preventing unplanned downtime.

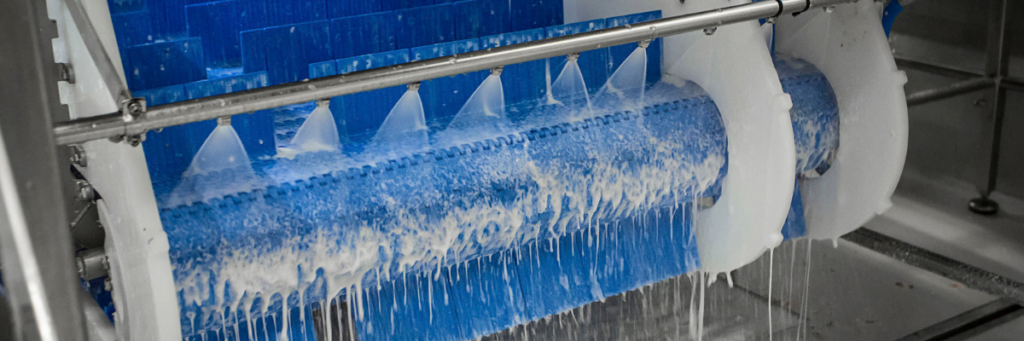

2. Cleaning Product Residue in Food and Beverage Industry

- Application: In food processing plants, conveyor belts can accumulate food particles, grease, and other organic residues. High-pressure cleaning is used to sanitize and clean conveyor belts, rollers, and surfaces without the use of harsh chemicals.

- Benefit: Regular high-pressure cleaning helps maintain hygienic conditions, reducing the risk of bacterial contamination and ensuring compliance with food safety regulations. Clean conveyor systems also ensure consistent product quality and reduce cross-contamination risks.

3. Removing Grease and Oil from Conveyor Components

- Application: In industries such as automotive, manufacturing, and oil refineries, conveyor systems often come into contact with grease, oil, and other lubricants. High-pressure cleaning systems are used to remove oil and grease buildup from conveyor belts, rollers, and other mechanical components.

- Benefit: Removing oil and grease ensures that conveyor components work efficiently, reduces slippage, and prevents excessive wear on mechanical parts. Clean components also improve workplace safety by reducing the risk of slips and fires.

4. Cleaning Pulleys and Rollers

- Application: Conveyor systems rely on pulleys and rollers to guide and support the belt. These components can become coated with debris, dust, or material residue from transported goods. High-pressure cleaning is used to remove buildup from pulleys, rollers, and bearings.

- Benefit: Regular cleaning of pulleys and rollers helps prevent belt misalignment, reduces mechanical strain on the system, and extends the life of the conveyor components. Clean rollers also maintain smooth operation and prevent belt damage.

5. Cleaning of Conveyors in Mining and Aggregate Industries

- Application: Conveyor systems in mining and aggregate industries transport materials like coal, gravel, sand, and minerals. These materials can create a significant amount of dust and debris, leading to blockages and wear on the conveyor components. High-pressure cleaning is used to remove these materials from conveyor belts and components.

- Benefit: High-pressure cleaning prevents blockages, reduces wear and tear, and ensures continuous material flow. This reduces maintenance costs and increases the lifespan of the conveyor system, preventing costly downtime due to clogged systems.

6. Sanitizing Conveyor Systems in Pharmaceutical and Cleanroom Environments

- Application: In pharmaceutical manufacturing and cleanroom environments, conveyor systems must be kept clean and sterile to prevent contamination. High-pressure cleaning is used to sanitize conveyor surfaces and eliminate dust, debris, and contaminants without disrupting production.

- Benefit: Regular cleaning ensures that conveyor systems comply with stringent cleanliness and sterility standards, preventing contamination of products and maintaining the quality of pharmaceuticals and other sensitive goods.

7. Cleaning of Chain Conveyors

- Application: Chain conveyors, often used in manufacturing and automotive industries, can accumulate dirt, grease, and other contaminants between the links and chains. High-pressure cleaning systems are used to thoroughly clean chain conveyors and remove buildup.

- Benefit: Clean chain conveyors reduce friction, minimize the risk of mechanical failure, and prolong the life of the conveyor system. Removing buildup also ensures smooth movement of the chain, reducing the risk of equipment jamming or damage.

8. Removing Adhesive and Sticky Residue

- Application: In industries like packaging and printing, conveyor systems can accumulate sticky residues from adhesives, inks, and tapes. High-pressure cleaning is used to remove these residues from belts and rollers.

- Benefit: Removing sticky residues prevents belts from sticking or slipping, which can cause jams and material handling issues. Clean conveyor belts also ensure smooth material flow and improve product quality by avoiding contamination from residues.

9. Cleaning Conveyor Systems in Recycling and Waste Management

- Application: Conveyor systems used in recycling and waste management facilities transport a variety of materials, including metals, plastics, and waste. These systems can accumulate debris, contaminants, and hazardous materials. High-pressure cleaning is used to remove these materials and clean the conveyor system.

- Benefit: Regular cleaning prevents blockages, improves conveyor performance, and ensures that the system operates safely and efficiently. It also helps reduce the risk of fire or contamination from hazardous materials present in recycling and waste management processes.

10. Cleaning of Elevating Conveyors

- Application: Elevating conveyors, which transport materials at an incline or vertical angle, are prone to dirt and residue buildup on both the conveyor belt and the inclined surfaces. High-pressure cleaning systems can effectively clean these conveyors and remove the debris.

- Benefit: Cleaning elevating conveyors ensures smooth material movement without interruptions and reduces the risk of material slippage, which can damage both the conveyor and the materials being transported.

11. Cleaning of Conveyor Systems in Cement Plants

- Application: Conveyor systems in cement plants handle materials such as cement, limestone, and aggregates, which generate significant dust and debris. High-pressure cleaning is used to remove dust buildup, cement residues, and contaminants from conveyor belts and rollers.

- Benefit: Regular cleaning of conveyors in cement plants prevents dust accumulation, which can interfere with production efficiency. Clean systems also minimize the risk of mechanical issues caused by the abrasive nature of cement particles, thus prolonging equipment life.

12. Maintaining Hygiene in Meat and Poultry Processing Plants

- Application: In meat and poultry processing plants, conveyor systems are exposed to blood, fat, tissue, and other organic matter that can attract bacteria and pathogens. High-pressure cleaning systems are used to clean and sanitize conveyor belts, chains, and rollers.

- Benefit: Regular cleaning ensures hygienic conditions, reduces the risk of cross-contamination, and helps meat and poultry processing plants meet food safety regulations. Clean conveyors also ensure product quality and safety.

13. Post-Shutdown and Maintenance Cleaning

- Application: After routine maintenance or production shutdowns, conveyor systems often need to be cleaned to remove debris, dust, or spilled materials. High-pressure cleaning is used to perform deep cleaning before resuming operations.

- Benefit: Cleaning conveyor systems after maintenance ensures they operate at optimal efficiency when production resumes. It also reduces wear on components by removing potentially abrasive debris left during maintenance activities.

14. Cleaning of Belt Scrapers and Spillage Systems

- Application: Belt scrapers and spillage systems, designed to remove excess material from the conveyor belt and prevent spills, can become clogged with material buildup. High-pressure cleaning systems are used to remove accumulated material from scrapers and spillage systems.

- Benefit: Regular cleaning of belt scrapers and spillage systems ensures proper functioning and prevents material buildup from affecting the conveyor belt’s performance. It also reduces the risk of material spilling onto the floor, improving workplace safety.

Conclusion

High-pressure cleaning systems play a critical role in maintaining conveyor systems across various industries. From removing dirt and debris to ensuring hygienic conditions in food processing plants, high-pressure cleaning improves the efficiency, safety, and longevity of conveyor systems. Regular cleaning prevents downtime, reduces wear and tear, and ensures smooth, continuous operation, making it an indispensable tool in conveyor system maintenance.