Water Jetting Units for Power Plants | Efficient Cleaning and Maintenance Solutions

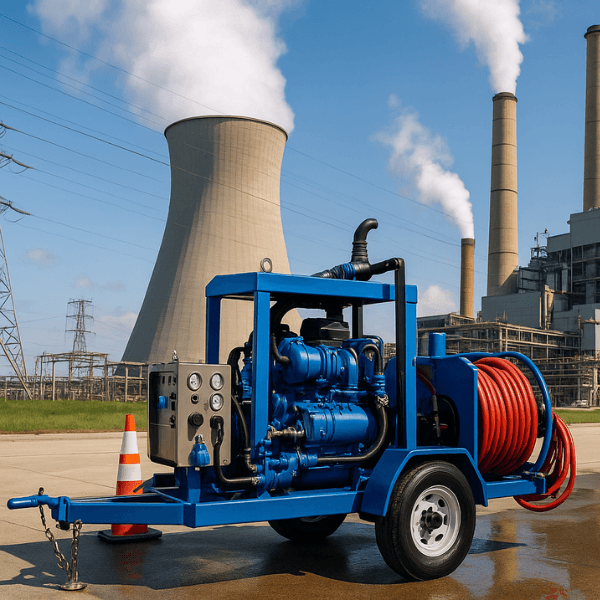

Water jetting units for power plants are powerful, high-pressure systems designed for the cleaning, maintenance, and descaling of critical equipment like heat exchangers, boilers, turbines, and condenser tubes. These systems offer an efficient and eco-friendly way to remove debris, scale, soot, and other buildup, helping to maintain optimal performance and reduce downtime in power generation facilities.

By utilizing advanced high-pressure water jetting technology, our units ensure safe, effective, and non-abrasive cleaning for your power plant equipment, ensuring longevity and improved efficiency.

How Water Jetting Units for Power Plants Work

Our water jetting units for power plants use high-pressure water streams (500 bar to 2800 bar) to dislodge and remove stubborn deposits and residues. Key components include:

How It Works

High-Pressure Pumps: Delivering water at the required pressure

Rotary Nozzles: Ensuring uniform cleaning across surfaces

Flexible Lances and Hoses: Reaching deep into equipment such as heat exchangers and tubes

Remote Control Systems: Enabling safe and easy operation

Key Benefits of Water Jetting Units for Power Plants

Water jetting technology is essential for power plants, ensuring that critical assets are properly maintained. The benefits include:

Enhanced Operational Efficiency – Removing scale, soot, and debris to improve heat exchange efficiency

Reduced Downtime – Faster cleaning and minimal disruption to operations

Eco-Friendly – Water-based cleaning method with no harmful chemicals

Cost-Effective – Lower maintenance and replacement costs by preventing damage to equipment

Increased Equipment Lifespan – Proper cleaning extends the life of boilers, heat exchangers, and turbines

Technical Specifications

- Pressure Range: 500 – 2800 bar (customizable for different needs)

- Flow Rate: 15 – 200 LPM

- Power Source: Diesel, Electric, or Hydraulic

- Pump Type: Triplex plunger pump for durability

- Mobility Options: Skid or trailer-mounted for easy transportation

- Accessories: Rotary nozzles, lance extension, surface cleaning tools

Applications in Power Plants

Water jetting units are essential for various applications within power plants, helping ensure smooth operations:

Heat Exchanger Cleaning: Removing fouling and scaling to improve heat transfer efficiency

Condensate and Condenser Tube Cleaning: Ensuring maximum heat transfer by cleaning cooling systems

Turbine Cleaning: Removing carbon and grease deposits from turbine blades and other components

Pipe Cleaning: Clearing build-up in pipes, valves, and other critical pipelines

Water jetting units are essential for various applications within power plants, helping ensure smooth operations:

Advantages of Our Water Jetting Units for Power Plants

Effective Cleaning: Capable of removing a wide range of materials including soot, scale, rust, and more

Non-Abrasive: Prevents damage to sensitive equipment, prolonging its lifespan

Energy-Efficient: Reduces energy consumption by improving heat transfer efficiency

Safe Operation: Equipped with remote controls for safe use in hazardous environments

Versatile: Can be adapted for various power plant systems including boilers, turbines, and condensers

Why Choose Our Water Jetting Units for Power Plants?

Our water jetting units are designed to meet the specific needs of power plants, offering:

Long-Term Reliability: Built for continuous operation in harsh industrial environments

Customizable Options: Designed to meet the requirements of your specific power plant equipment

Maintenance-Free Design: Durable pumps and nozzles for low-maintenance operation

Fast Setup: Minimal downtime with easy-to-install equipment

FAQ

Pressure typically ranges from 500 bar to 2800 bar, depending on the scale and type of equipment being cleaned.

No, high-pressure water jetting is non-abrasive and safe for sensitive components when used correctly.

By removing deposits from critical equipment like heat exchangers and boilers, it restores heat transfer efficiency, preventing performance losses.

Cleaning frequency depends on the type of equipment and usage. Typically, water jetting is performed during scheduled maintenance or when fouling is observed.