Water Jetting Systems for Heat Exchanger Cleaning | Efficient, Eco-Friendly Cleaning Solutions

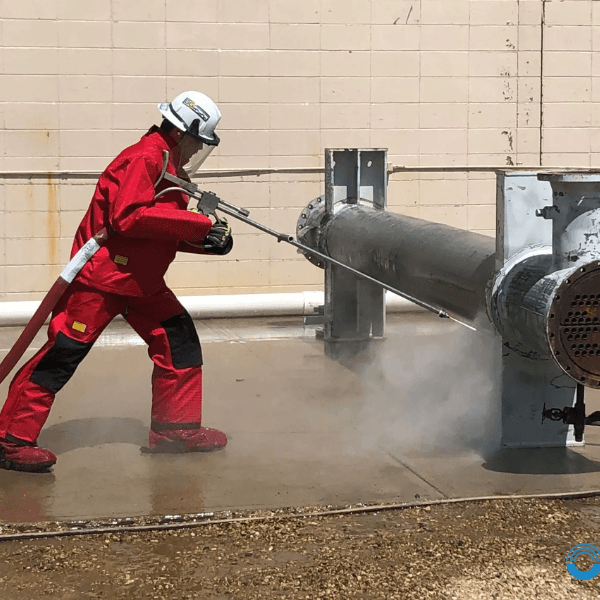

Water jetting systems for heat exchanger cleaning provide a highly effective and eco-friendly solution to remove scale, fouling, and debris that impair heat transfer efficiency. Whether in chemical plants, petrochemical refineries, or power generation facilities, our water jetting systems ensure that heat exchangers operate at peak performance, improving energy efficiency and reducing operational costs.

Utilizing high-pressure water jets, these systems can clean heat exchangers quickly, without the need for harsh chemicals or abrasives, protecting equipment and ensuring minimal downtime.

How Water Jetting Systems Work for Heat Exchanger Cleaning

Our high-pressure water jetting systems deliver pressurized water (ranging from 500 bar to 2800 bar) through specially designed nozzles. The systems are equipped with various components to ensure effective cleaning:

How It Works

High-Pressure Pump: Delivers the required pressure for effective cleaning

Rotary Nozzles: Ensure uniform coverage and optimal cleaning of heat exchanger tubes

Flexible Lances & Hoses: Reach deep into the tubes, effectively cleaning difficult-to-access areas

Automated Control Systems: Allow precise regulation of pressure and flow for different cleaning applications

Rotary Tube Cleaning Technology: Spins nozzles inside the tubes, breaking apart deposits and removing them

Technical Specifications

- Pressure Range: 500 – 2800 bar (customizable for different heat exchanger types)

- Flow Rate: 15 – 200 LPM

- Power Source: Diesel, Electric, or Hydraulic

- Nozzle Type: Rotary nozzles for deep cleaning and uniform coverage

- Accessories: Flexible lances, hose reels, surface cleaning nozzles

- Control Options: Manual, semi-automatic, or fully automated for safe operation

- Mounting: Skid or trailer-mounted for portability

Applications of Water Jetting Systems for Heat Exchanger Cleaning

Water jetting systems are essential for maintaining the performance and longevity of heat exchangers in various industries:

Chemical Processing Plants: Removing scale, fouling, and debris from heat exchangers

Petrochemical Refineries: Cleaning heat exchangers used in distillation and other processes

Power Plants: Descaling and cleaning boilers, condensers, and heat exchangers

Food & Beverage Industry: Ensuring hygienic cleaning of heat exchangers used in pasteurization, refrigeration, and sterilization

Pharmaceutical Plants: Cleaning heat exchangers to maintain sterility and efficiency

Advantages of Water Jetting Systems for Heat Exchanger Cleaning

Efficient Performance: Quickly and effectively removes scale, rust, and other residues that impede heat transfer

Eco-Friendly Solution: No chemicals are used, making it safer for the environment and workers

Cost Savings: Reduces maintenance costs by preventing damage to heat exchanger surfaces

Low Downtime: Cleaning can be performed in a fraction of the time compared to traditional methods

Safe and Non-Abrasive: Prevents equipment damage, extending the lifespan of heat exchangers

Why Choose Our Water Jetting Systems for Heat Exchanger Cleaning?

Our water jetting systems are custom-designed to offer high-efficiency cleaning for various types of heat exchangers, ensuring that your equipment runs smoothly. Benefits include:

Versatility: Ideal for all types of heat exchangers, including plate, shell, tube, and spiral types

Customizable Solutions: Tailored to meet your specific pressure, flow, and nozzle requirements

Reliable & Durable: Built with high-quality materials to withstand the rigors of industrial cleaning

Eco-Friendly Design: No harmful chemicals or abrasive materials, reducing your environmental footprint

Expert Support: We offer installation, training, and ongoing support to ensure the optimal performance of your system

FAQ

The pressure typically ranges from 500 bar to 2800 bar, depending on the fouling level and type of heat exchanger.

Water jetting removes scale, fouling, and debris from tubes, restoring heat transfer efficiency and improving overall system performance.

Yes, our water jetting systems are versatile and can clean shell & tube, plate, spiral, and other types of heat exchangers.

Yes, water jetting is non-abrasive, meaning it removes deposits without damaging the heat exchanger surface or tubes.