Reactor Water Jet Cleaning Systems | High-Pressure Jet Cleaning Solutions

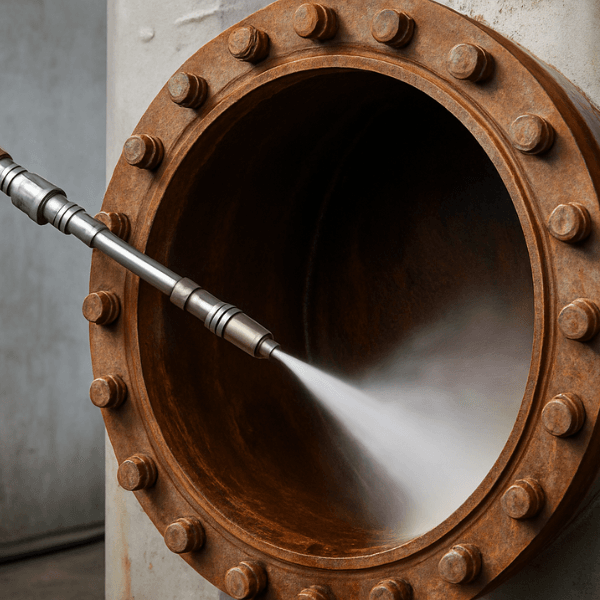

Reactor water jet cleaning systems are specialized high-pressure cleaning solutions designed for industrial reactors in chemical, pharmaceutical, and petrochemical plants. These systems ensure safe, efficient, and residue-free cleaning without causing any damage to reactor walls or internal components.

The Challenge of Cleaning Skyscrapers

Over time, reactors accumulate scale, polymer deposits, coke, catalyst residues, and other stubborn contaminants that affect performance and yield. Traditional manual cleaning is time-consuming and unsafe. High-pressure water jet cleaning systems offer:

100% residue removal for optimum performance

Reduced downtime and faster turnaround

Environmentally friendly cleaning – no harsh chemicals

Safe operation for confined spaces

How Reactor Water Jet Cleaning Systems Work

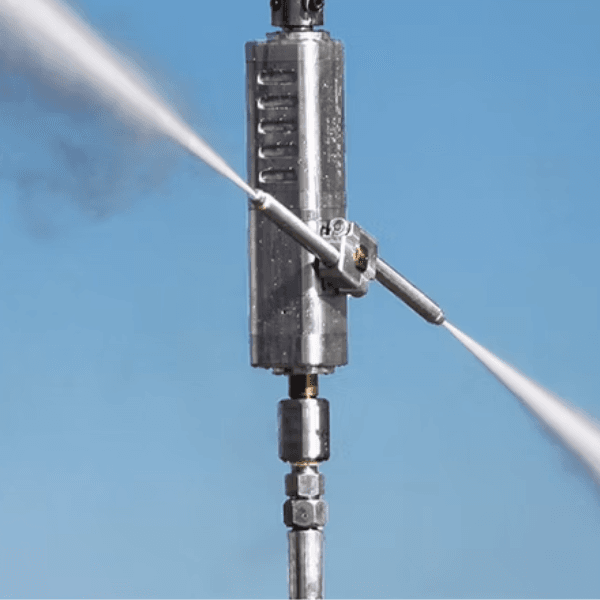

Our reactor water jet cleaning systems use ultra-high-pressure water jets (typically 500 bar to 1500 bar or more) to dislodge deposits without damaging reactor surfaces. The system includes:

How It Works

High-pressure pump unit

Specialized nozzles and rotary jet heads

Flexible lance or automated nozzle positioning system

Remote control for safe operation

Technical Specifications

- Pressure Range: 500 to 1500 bar (customizable up to 3000 bar)

- Flow Rate: 20 LPM to 200 LPM

- Power Source: Electric / Diesel

- Automation Options: Manual, Semi-Automatic, Fully Automated

Applications of Reactor Water Jet Cleaning

Our cleaning systems are widely used in:

Chemical Processing Reactors – removing polymer residues, chemical deposits

Pharmaceutical Reactors – ensuring sterile, clean surfaces

Petrochemical Reactors – eliminating coke and catalyst build-up

Food & Beverage Reactors – hygienic and contamination-free cleaning

Advantages of Our Reactor Water Jet Cleaning Systems

Cost-Effective – Reduces labor and downtime costs

Automation Available – Improves safety in hazardous environments

High Efficiency – Reduces cleaning cycle time

Non-abrasive & Non-chemical – Protects equipment life

Why Choose Us?

We provide custom-designed water jet cleaning systems for reactors with:

Advanced technology for deep cleaning

Robust high-pressure pumps and accessories

On-site installation & training

24/7 technical support

FAQ

Typically, 500 to 1500 bar high-pressure jets are used for safe and effective cleaning.

No. When done correctly, it is non-abrasive and safe for internal linings.

Depending on size and deposit level, it takes 50% less time compared to manual methods.