Industrial Water Jet Tube Cleaning System | Efficient Tube and Pipe Cleaning Solutions

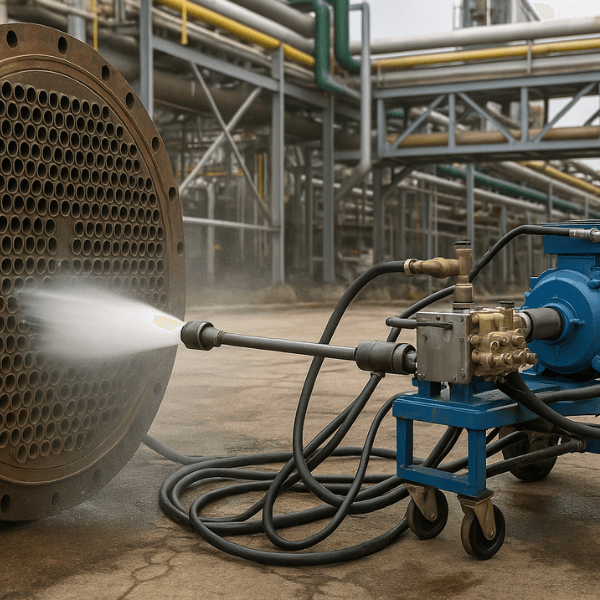

Industrial water jet tube cleaning systems are high-performance, high-pressure cleaning units designed for cleaning and descaling tubes, pipes, and other critical components in various industrial settings. These systems are perfect for cleaning heat exchangers, boilers, condensers, and other tube-based equipment, ensuring optimal performance and efficiency.

Our industrial water jetting systems are engineered to remove scale, dirt, grease, and other build-ups from the inner surfaces of tubes and pipes without causing any damage, reducing downtime and maintenance costs while improving system efficiency.

How Industrial Water Jet Tube Cleaning Systems Work

Industrial water jetting systems use high-pressure water jets (500 bar to 2800 bar) to dislodge and flush away scale, dirt, and other deposits from tube and pipe interiors. These systems consist of:

How It Works

High-Pressure Pump: Delivers water at the required pressure

Rotary Nozzles: Spins and ensures uniform cleaning across tube surfaces

Flexible Lances: Reach deep into the tubes, allowing access to difficult-to-clean areas

Control Systems: Allow for easy monitoring and safe operation

Technical Specifications

- Pressure Range: 500 – 2800 bar

- Flow Rate: 15 – 200 LPM

- Power Source: Diesel, Electric, or Hydraulic

- Nozzle Type: Rotary nozzles for uniform coverage

- Mounting Options: Skid or Trailer-mounted for easy transport

- Accessories Available: Lance extension, reel systems, surface cleaning nozzles

Applications of Industrial Water Jet Tube Cleaning Systems

Our water jet tube cleaning systems are used across various industries to ensure that critical equipment is maintained and operated efficiently:

Heat Exchanger Cleaning: Removes fouling and scaling to restore heat transfer efficiency

Boiler Tube Cleaning: Clears ash, soot, and scale build-up in industrial boilers

Condenser Tube Cleaning: Ensures maximum heat transfer in cooling systems

Marine Industry: Cleaning of ship hulls and engine components

Food & Beverage Industry: Cleaning of piping systems in food processing plants

Chemical & Petrochemical Plants: Maintaining reactors and pipelines to prevent clogging

Benefits of Using Water Jet Tube Cleaning Systems

Efficient Cleaning: High-pressure jets remove even the toughest deposits quickly

Non-Invasive: Prevents damage to tubes and pipes

Eco-Friendly: No chemicals or abrasives are used, ensuring a safer operation

Improved System Performance: Restores the original efficiency of heat exchangers, boilers, and condensers

Minimal Downtime: Fast cleaning reduces overall downtime during maintenance cycles

Why Choose Our Industrial Water Jet Tube Cleaning Systems?

Our systems are designed for high performance and durability, providing long-term cleaning solutions for industrial applications:

Customizable Options: Tailored to fit the cleaning requirements of your tubes and pipes

Robust Design: Built to handle tough cleaning tasks in industrial environments

Flexible & Portable: Available in skid or trailer-mounted models for easy mobility

Reliable Support: Full technical support and training for system installation and operation

FAQ

The pressure typically ranges from 500 to 2800 bar, depending on the thickness of the deposits and the type of equipment being cleaned.

Water jet cleaning is more efficient, faster, and safer than manual cleaning, and it avoids damage to the equipment since no abrasives or chemicals are used.

Yes, our systems can be used for a wide range of tubes, including metal, plastic, and composite tubes.

Tube cleaning should be done regularly as part of scheduled maintenance or when fouling is detected to ensure that the system is running at peak efficiency.