High Pressure Water Jetting Pumps | Efficient and Durable Industrial Cleaning Solutions

High-pressure water jetting pumps are essential components for delivering powerful water streams in industrial cleaning applications. These pumps are designed to generate high-pressure water (up to 2800 bar) for a range of tasks, including cleaning, descaling, degreasing, and surface preparation.

Whether you need to clean pipes, heat exchangers, boilers, or industrial machinery, our high-pressure water jetting pumps ensure efficient, eco-friendly, and cost-effective cleaning solutions.

How High Pressure Water Jetting Pumps Work

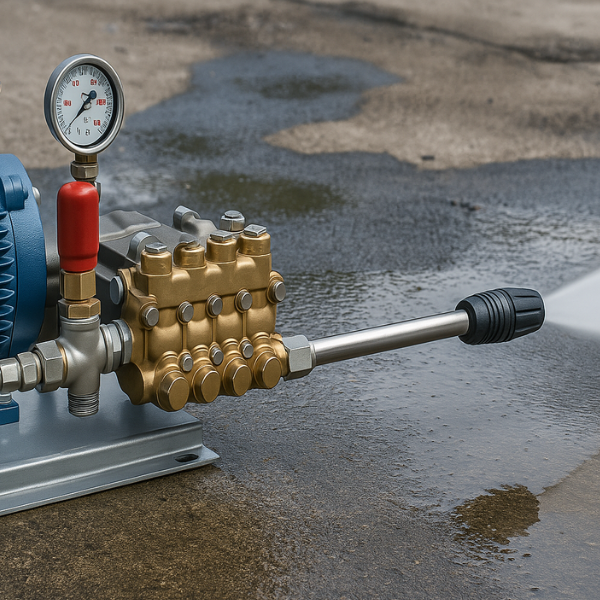

High-pressure water jetting pumps use a powerful pump mechanism to generate high-pressure water streams. The basic components include:

How It Works

High-Pressure Pump: The core of the system, delivering the required pressure to the water stream (typically up to 2800 bar)

Motor: Drives the pump, typically powered by electric, diesel, or hydraulic power sources

Nozzles: Direct the water stream, with various nozzle types available for different cleaning applications, including rotary nozzles and fixed nozzles

Flexible Hoses & Lances: Allow the water to reach deep into pipes, tubes, and hard-to-access areas

Control System: Regulates water pressure and flow, providing precise control for various applications

Technical Specifications

- Pressure Range: 500 – 2800 bar (customizable for different applications)

- Flow Rate: 15 – 200 LPM

- Power Sources: Electric, Diesel, Hydraulic-powered systems

- Pump Type: Triplex Plunger Pumps, Axial Piston Pumps, or Gear Pumps

- Motor Power: From 5 HP to 400 HP, depending on application needs

- Materials: Constructed from high-quality, corrosion-resistant materials for durability

- Mounting Options: Skid, Trailer, or Vehicle-mounted for mobility

- Accessories: Rotary nozzles, surface cleaning attachments, flexible hoses, hose reels

Applications of High Pressure Water Jetting Pumps

High-pressure water jetting pumps are widely used in various industries for cleaning, maintenance, and surface preparation tasks:

Pipe & Tube Cleaning: Removes scale, rust, and grease from pipes and tubes in chemical, pharmaceutical, and power industries

Heat Exchanger Cleaning: Efficiently cleans heat exchanger tubes, restoring heat transfer efficiency

Boiler & Condenser Cleaning: Removes soot, ash, and scale buildup, improving operational efficiency and reducing energy consumption

Surface Cleaning: Cleans large surfaces, including concrete, steel, and metal, removing contaminants like grease, oil, and dirt

Marine Industry: Cleans ship hulls, turbines, and offshore platforms, removing marine growth and fouling

Food & Beverage Industry: Hygienically cleans pipes and machinery without the use of harmful chemicals

Benefits of Using High Pressure Water Jetting Pumps

Highly Effective: Can remove even the most stubborn contaminants such as grease, rust, and scale

Safe and Non-Damaging: Non-abrasive action ensures that no damage occurs to equipment, prolonging its lifespan

Environmentally Friendly: Eliminates the need for harsh chemicals, reducing environmental impact

Reduced Downtime: Fast and efficient cleaning reduces maintenance downtime and increases productivity

Low Operating Costs: Provides a long-lasting, low-maintenance solution for industrial cleaning tasks

Why Choose Our High Pressure Water Jetting Pumps?

Our high-pressure water jetting pumps are designed to provide the most efficient and powerful cleaning solutions for industrial applications. Here’s why they stand out:

Reliable Performance: High-quality construction ensures durability and long-lasting performance

Wide Range of Applications: Suitable for cleaning pipes, tanks, heat exchangers, turbines, and more

Energy Efficient: Advanced pump designs that minimize energy consumption without compromising on performance

Customizable Options: Tailored systems to meet your specific pressure, flow, and nozzle requirements

Expert Support: We provide full installation, training, and after-sales support to ensure seamless operation

FAQ

High-pressure water jetting pumps can generate pressures ranging from 500 bar to 2800 bar, depending on the cleaning needs and equipment being cleaned.

The high-pressure water stream effectively breaks apart stubborn contaminants such as scale, grease, rust, and dirt, significantly improving cleaning speed and efficiency.

Yes, water jetting is non-abrasive, ensuring that even delicate equipment is cleaned without the risk of damage.

These pumps are widely used in industries such as chemical processing, pharmaceuticals, marine, oil & gas, food processing, and power generation.