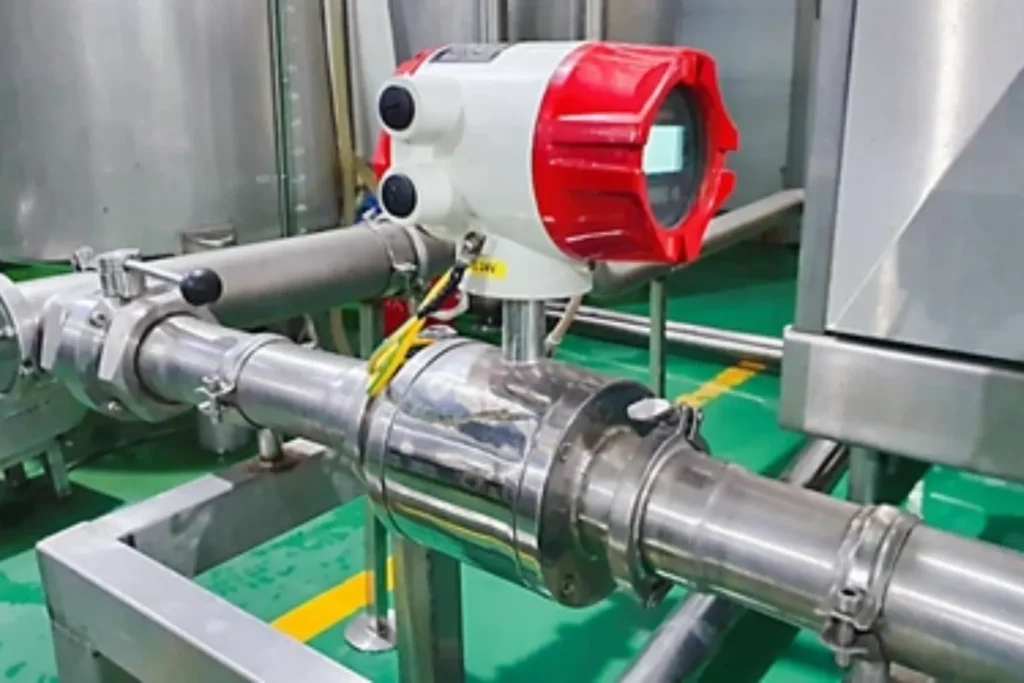

High Pressure Flow Sensor in India

Riggers Pump is a leading supplier of high pressure flow sensors in India, delivering precision monitoring solutions for industries that demand accuracy, durability, and safety. Our flow sensors are designed for pressure washers, hydraulics, chemical processing, oil & gas, and industrial water jetting systems, with ranges from 70 bar to 1000 bar (1000 PSI to 14,500 PSI).

Engineered with robust materials and advanced sensing technology, our industrial high pressure flow sensors provide reliable data for controlling flow and pressure in demanding applications.

Features of High Pressure Flow Sensors

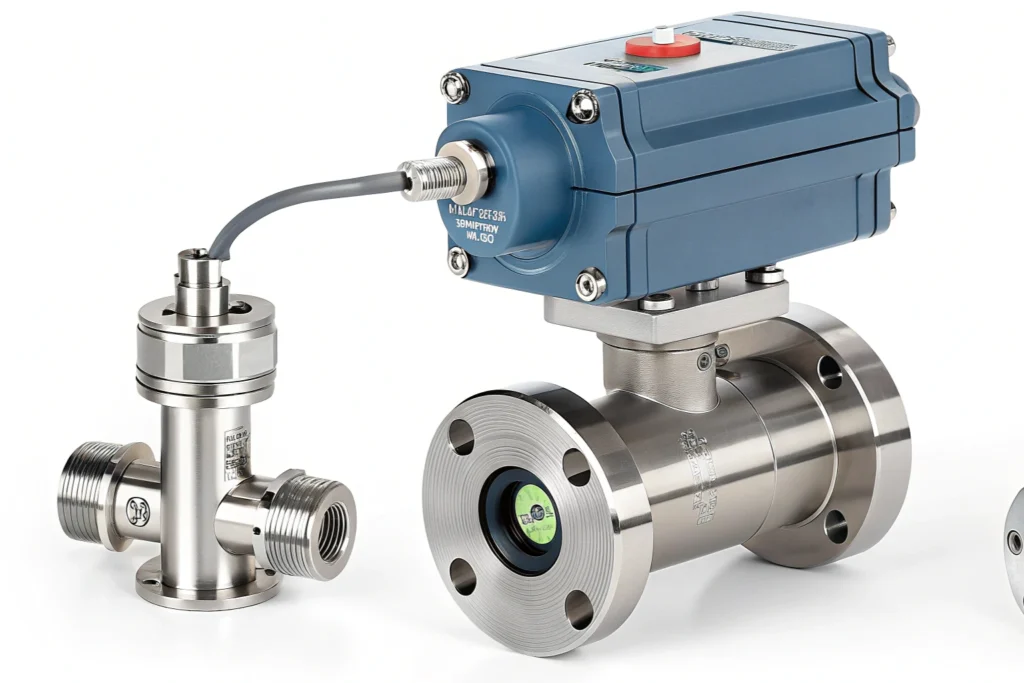

Robust and Durable Build

High-Pressure Tolerance: Rated for pressures up to 10,000 PSI and beyond, ideal for extreme industrial use.Corrosion-Resistant Materials: Available in stainless steel, titanium, and high-grade alloys for harsh environments. Temperature Resistance: Performs in both high and low temperature conditions.

Accuracy and Sensitivity

High Precision: ±0.5% to ±1% full-scale accuracy ensures consistent flow monitoring.High Sensitivity: Detects even small changes in flow rate. Repeatability and Stability: Minimal drift for long-term accuracy.

Wide Range of Flow Measurement

Broad Flow Range: Measures both low and high flow rates accurately.Bi-Directional Sensing: Capable of detecting flow in both directions.

Compatibility with Various Media

Multi-Fluid Performance: Works with water, oils, fuels, gases, and chemicals. Optional Non-Intrusive Designs: Prevents contamination and reduces downtime.

Real-Time Data Monitoring and Output

Fast Response Time: Near-instant feedback for dynamic systems.Analog & Digital Outputs: Options include 4–20mA, 0–10V, and digital signals for PLC/SCADA integration. Data Logging Capability: Advanced models allow data storage for diagnostics and performance analysis

Easy Installation and Maintenance

Compact Design: Space-saving footprint for tight installations.Modular Assembly: Easy maintenance and component replacement.Self-Diagnostics: Alerts for calibration, health status, and performance.

Vibration and Shock Resistance

Anti-Vibration Design: Stable readings in high-vibration environments.Secure Mounting Options: Prevents sensor displacement under stress.

Compliance and Certifications

Certified for Industrial Applications: Meets CE, ATEX, and UL standards.High IP/NEMA Ratings: IP65/IP67 or NEMA 4/4X protection against dust and water ingress.

Applications of High Pressure Flow Sensors

Oil & Gas Industry

Pipeline Monitoring: Monitors crude oil, natural gas, and refined product flows.Wellhead & Subsea Monitoring: Withstands extreme pressures and subsea conditions

Hydraulic Systems

Automotive & Industrial Hydraulics: Maintains oil flow in injection molding, presses, and automotive systems.Mobile Equipment: Provides precise flow monitoring in excavators, cranes, and heavy machinery.

Chemical Processing

Injection & Dosing Systems: Maintains precise chemical flow under pressure.Corrosive Fluids: Resistant to aggressive chemical environments.

Water Treatment & Management

Reverse Osmosis Plants: Monitors flow for desalination and purification.High-Pressure Cleaning: Ensures correct flow in industrial washers.

Automotive Industry

Fuel Injection Systems: Measures fuel flow in direct injection engines.Engine Calibration Benches: Supports accurate testing and development

Food & Beverage Processing

High-Pressure Pasteurization: Ensures quality and compliance in food safety processes.Carbonation Systems: Maintains CO₂ flow for consistent beverage production.

Why Choose Riggers Pump for High Pressure Flow Sensors?

Riggers Pump is a leading manufacturer and supplier of high pressure flow sensors in India, delivering solutions trusted by oil & gas, hydraulics, water jetting, and process industries.

Our industrial high pressure flow sensors are built for ±0.5% to ±1% accuracy, ensuring reliable flow and pressure monitoring.

We supply stainless steel high pressure flow sensors and titanium options, resistant to corrosion, chemicals, and extreme temperatures.

From digital high pressure flow sensors with PLC/SCADA outputs to hydraulic models for heavy machinery, we provide cutting-edge solutions.

All sensors comply with CE, ATEX, and ISO standards, ensuring safety in hazardous and high-pressure environments.

Installation, calibration, spare parts, and after-sales service from a proven Indian supplier.

FAQs on High Pressure Flow Sensors

A high pressure flow sensor measures the flow rate and pressure of fluids in systems operating from 70 bar up to 1000 bar (1000 to 14,500 PSI), ensuring accuracy and safety in industrial processes.

Our sensors are widely used in oil & gas, hydraulic systems, water jet cutting, chemical processing, automotive fuel injection, and food & beverage industries.

We offer stainless steel high pressure flow sensors for corrosive environments such as chemical plants, marine industries, and water treatment facilities.

Yes. We provide hydraulic high pressure flow sensors for automotive hydraulics, heavy machinery, and industrial presses.

Our digital high pressure flow sensors support real-time monitoring and integration with PLC/SCADA systems for automation and process control.

Our sensors provide high precision monitoring with accuracy levels of ±0.5% to ±1% full-scale, ensuring consistent performance.

Because we are a trusted supplier of high pressure flow sensors in India, offering certified quality, durable construction, customization, and complete after-sales support.