High Pressure Electric Water Jetting Systems | Advanced Industrial Cleaning Solutions

High-pressure electric water jetting systems provide a safe, cost-effective, and eco-friendly cleaning solution for a wide range of industrial applications. Powered by electricity, these systems deliver powerful water jets (up to 2800 bar) to clean, descale, and remove stubborn residues from various surfaces, including pipes, tubes, heat exchangers, and boilers. They are ideal for operations where efficient cleaning is required without the use of harmful chemicals or abrasives.

Our high-pressure electric water jetting systems are designed for both light-duty and heavy-duty industrial cleaning, ensuring that your equipment operates at peak performance.

How High Pressure Electric Water Jetting Systems Work

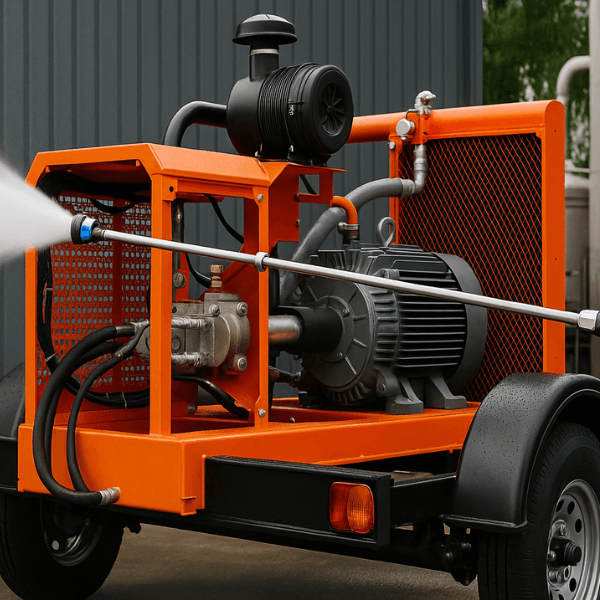

High-pressure electric water jetting systems use a high-pressure pump, powered by an electric motor, to force water through nozzles at extremely high pressures (500 bar to 2800 bar). The system components include:

How It Works

Electric Motor: Powers the pump with high energy efficiency and low operational costs

High-Pressure Pump: Provides the necessary pressure for effective cleaning

FRotary Nozzles: Spin and ensure uniform coverage for consistent cleaning

Flexible Hoses & Lances: Reach deep into pipes, tubes, and hard-to-reach areas

Control System: Allows easy regulation of pressure and flow for different applications

Technical Specifications

- Pressure Range: 500 – 2800 bar (customizable to suit application needs)

- Flow Rate: 15 – 200 LPM

- Power Source: Electric Motor (single-phase or three-phase)

- Pump Type: Triplex plunger pump or gear pump for maximum reliability

- Mounting Options: Skid or Trailer-mounted for portability

- Accessories: Rotary nozzles, lance extensions, hose reels, surface cleaning attachments

Applications of High Pressure Electric Water Jetting Systems

High-pressure electric water jetting systems are designed to meet the demanding cleaning needs of various industries:

Pipe & Tube Cleaning: Removing rust, scale, and grease from pipes, heat exchangers, and boilers

Surface Preparation: Cleaning metal surfaces, concrete, and machinery parts

Descaling: Removing scale and fouling from industrial equipment

Marine Industry: Cleaning ship hulls, offshore structures, and marine engines

Food & Beverage Industry: Hygienic cleaning of piping systems without harmful chemicals

Chemical & Petrochemical Plants: Cleaning reactors, pipelines, and tanks to ensure smooth operations

Benefits of High Pressure Electric Water Jetting Systems

Eco-Friendly & Sustainable: No chemicals are needed, reducing environmental impact

Cost-Effective Operation: Electricity is more affordable than diesel or hydraulic fuel

Quiet & Safe: Operates without noise and exhaust fumes, making it suitable for indoor and confined space applications

Efficient Cleaning: Quickly removes scale, rust, and other deposits without damaging surfaces

Low Maintenance: Electric motors require less maintenance compared to other power sources

Why Choose Our High Pressure Electric Water Jetting Systems?

Our electric-powered water jetting systems are designed for high performance, offering numerous advantages over traditional cleaning methods:

Energy Efficient: Our electric systems consume less power than diesel-powered models, reducing operating costs

Safe for Indoor Use: No exhaust emissions, making them perfect for confined spaces

Portable & Compact: Available in skid or trailer-mounted units for easy transport

Reliable & Durable: Built with high-quality components to withstand industrial use and provide long-term performance

FAQ

Electric systems eliminate the need for chemicals and abrasives, providing a clean, environmentally safe solution for industrial cleaning.

By using high-pressure water, the system quickly and effectively removes even the toughest deposits like scale, rust, and grease from pipes, tubes, and surfaces.

Yes, since they operate with no exhaust fumes and are quiet, they are ideal for use in confined spaces and indoor areas.

The frequency of cleaning depends on the type of equipment and usage. Regular cleaning helps maintain optimum performance and reduce maintenance costs.