Industrial Electrical Panels for High Pressure Pumps

Riggers Pumps, a trusted supplier and dealer of electrical panels for high-pressure pumps in India, provides robust and reliable solutions for industrial and high-pressure washing applications.

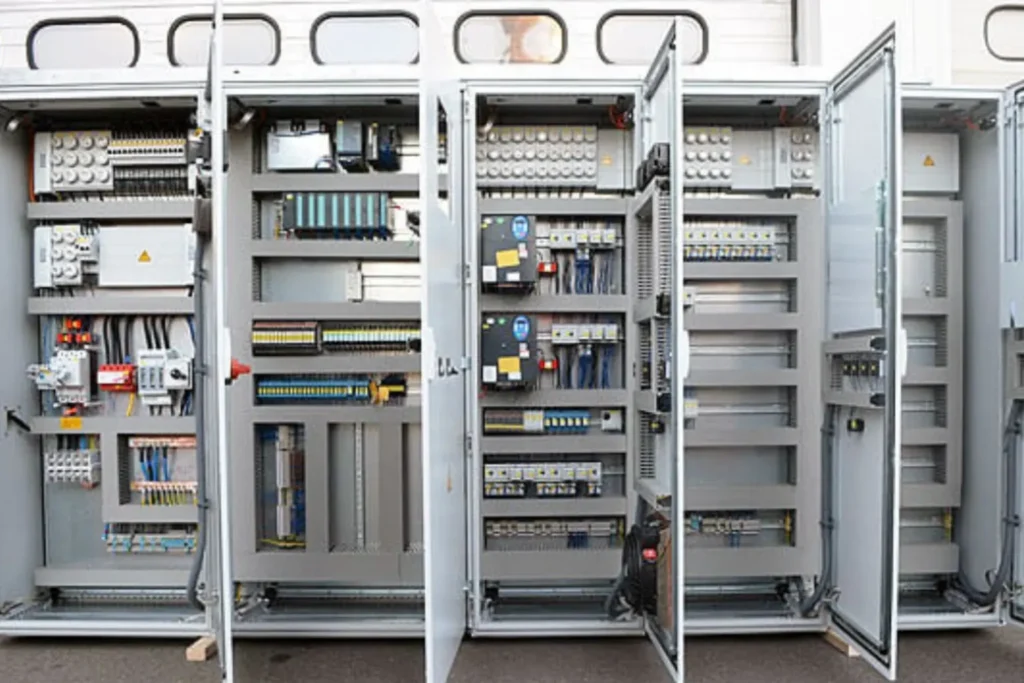

High-pressure pump systems require advanced electrical control panels that integrate safety, automation, and efficiency features. Our panels are designed to manage electric and diesel high-pressure pumps, ensuring optimal performance while protecting both operators and equipment. Whether it’s for industrial cleaning, hydro jetting, descaling, or farm and stable cleaning, our high-pressure electrical control panels are engineered to meet demanding environments and operational requirements.

Why Electrical Panels Are Critical for High-Pressure Pumps

Operational Efficiency – Automates pump control, flow rate, and pressure adjustments for consistent performance.

Safety & Compliance – Protects operators and equipment with built-in overload, short-circuit, and emergency stop mechanisms.

Equipment Longevity – Soft start/stop and VFD integration reduce mechanical stress and extend pump life.

Industrial Reliability – Designed for continuous heavy-duty operations, even in harsh environments.

Features of Riggers Pumps Electrical Panels

Robust Enclosure

Robust Enclosure

- Material: Stainless steel or corrosion-resistant materials for durability.

- IP/NEMA Rating: IP65/IP66 or NEMA-certified to resist water, dust, and debris.

Intelligent Control System

- PLC Integration: Customizable automation for pump control, fault monitoring, and system integration.

- HMI Interface: Easy monitoring of pressure, flow, system status, and alarms.

- Remote Control Capabilities: Enables safe, wireless operation from a distance.

Variable Frequency Drive (VFD) Integration

- Adjustable Pressure Control: Precisely manage pump speed and conserve energy.

- Soft Start/Stop: Protects pumps and motors from mechanical shock.

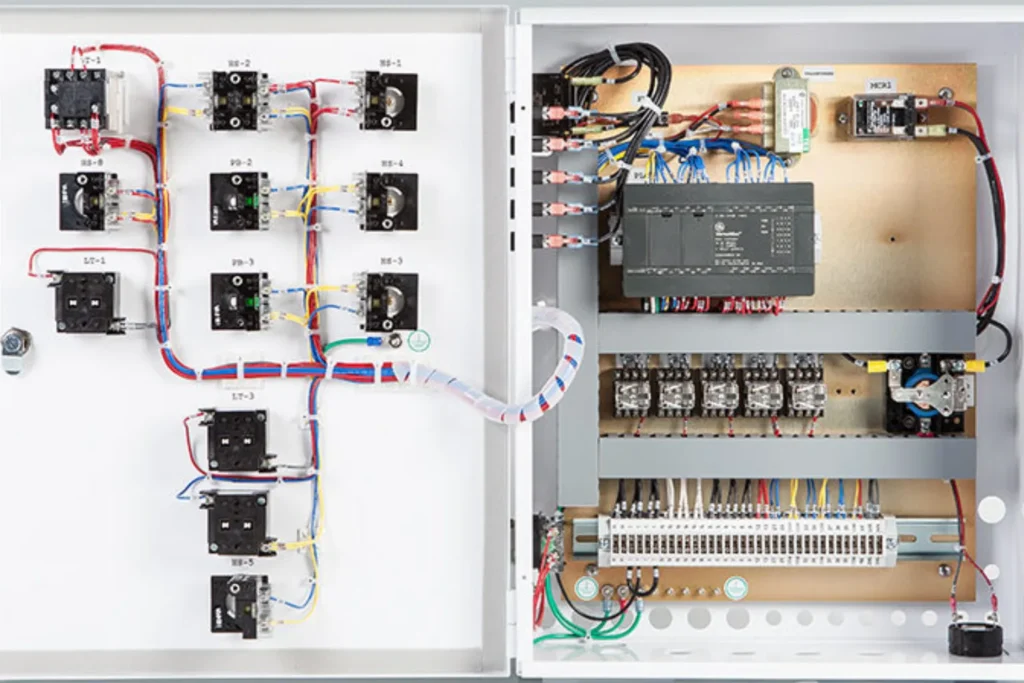

Safety Features

- Overload & Short Circuit Protection: Circuit breakers and relays reduce equipment damage.

- Emergency Stop Button: Quick shutdown in emergencies.

- Pressure & Temperature Sensors: Automatic alerts and shut-offs if thresholds are exceeded.

Digital Display & Alarms

- Real-Time Monitoring: Displays pressure, voltage, current, and temperature.

- Alarm Indicators: Visual and audible warnings for overpressure or system faults.

Thermal Management

- Cooling Systems: Fans or ventilation units prevent overheating during continuous operation.

- Heat Dissipation Materials: Optimized design to disperse heat effectively.

Efficient Wiring & Layout

- Organized Wiring: Clear labeling and separation of high- and low-voltage circuits.

- Compact Design: Optimized for ease of maintenance and space efficiency.

Compliance and Certifications

- Certifications: UL, CE, IEC-approved for industrial safety and quality.

- Industry Standards: NFPA and ISO-compliant for high-pressure pump systems.

Environmental Resistance

- Vibration & Shock Resistance: Durable in high-vibration industrial environments.

- Corrosion & UV Protection: For outdoor or corrosive environments.

Types of Descaling Pumps and Systems

Manual Control Panels

Simple start/stop operations for small pumps.

Automatic Control Panels

Sensor-based or timed operation for continuous applications.

PLC-Controlled Panels

Full automation with fault monitoring, alarms, and integration with pump systems.

Custom Electric Panels

Designed for mobile or fixed high-pressure pump setups.

Applications of pump electrical control panel

Industrial Cleaning & Hydro Jetting – Factories, warehouses, and industrial plants.

Farm & Stable Cleaning – High-pressure water systems for hygienic cleaning.

Descaling Systems – Boilers, pipes, and heat exchangers.

Construction & Civil Applications – Road, pavement, and building cleaning.

Food, Beverage & Pharmaceutical Plants – Hygienic cleaning in processing units.

Benefits of high-pressure pump control panel

Reliable Operation: Protects pumps and motors for consistent performance.

Enhanced Safety: Safety features prevent accidents and damage.

Operational Efficiency: Automates processes to reduce labor and downtime.

Durability: Designed for industrial, harsh, and wet environments.

Customizable Solutions: Panels tailored for electric or diesel pumps, manual or automated control.

Why Choose Riggers Pumps for Electrical Panels for High-Pressure Pumps

Riggers Pumps is a leading supplier and dealer of high-pressure pump electrical panels in India, delivering reliable and industrial-grade solutions.

Our electrical panels are designed for continuous heavy-duty operations, suitable for electric and diesel high-pressure pumps.

We offer manual, automatic, and PLC-integrated panels, tailored to your pump type, flow rate, and application requirements.

Our team provides complete guidance on installation, operation, and maintenance, ensuring optimal performance and reduced downtime.

Panels come with overload protection, emergency stop, pressure and temperature sensors, and comply with industrial safety standards.

Automates pump cycles, optimizes energy use, and reduces labor and water consumption for industrial cleaning and descaling systems.

Built to withstand harsh industrial environments, corrosion, and vibration, ensuring long-term performance.

Proven expertise and experience in industrial high-pressure pump systems, ensuring trustworthy and technically sound solutions.

FAQ for electrical panel for high-pressure pump

It is a control unit that manages the operation, safety, and automation of electric or diesel high-pressure pumps, including pressure regulation, motor protection, and remote monitoring.

Yes, diesel pump panels are custom-designed to handle motor control, pressure regulation, and integration with high-pressure systems safely.

Yes, we supply automatic truck and lorry washing machines with foam wash, high-pressure jets, and rinse systems — suitable for bus depots, fleet operators, and logistics yards.

Safety mechanisms include emergency stop buttons, overload relays, pressure and temperature sensors, and automatic shut-offs, protecting both the operator and the pump.

PLC-based panels provide full automation, real-time monitoring, and fault detection, ideal for industrial setups requiring precision and efficiency.

Yes, Riggers Pumps offers custom electrical panels for both manual and automated systems, suitable for industrial cleaning, hydro jetting, descaling, and farm/stable applications.